When it comes to measuring the flow of liquids in industrial systems, insertion flow meters offer a cost-effective and reliable solution. However, one of the most critical factors that often gets overlooked is matching the flow meter to your pipe size. Choosing the right insertion flow meter for your specific pipe diameter isn’t just a matter of compatibility—it directly affects accuracy, installation ease, and long-term performance.

This comprehensive guide will walk you through everything you need to consider to confidently select the right insertion flow meter for your pipe size. Whether you’re dealing with water, chemicals, wastewater, or any conductive fluid, these expert tips will help you avoid costly mistakes and maximize your measurement accuracy.

1. What Is an Insertion Flow Meter and Why Pipe Size Matters

An insertion flow meter is a type of flow measuring device where the sensor probe is inserted directly into the pipe to measure the velocity of fluid passing through. Unlike full-bore meters that span the entire diameter of the pipe, insertion meters only sample a part of the flow profile and use algorithms to estimate total flow.

Here’s why pipe size is so important:

-

It influences sensor positioning for accurate velocity profiling.

-

It affects installation method and whether hot tapping is viable.

-

Larger pipes may require deeper sensor insertion or custom calibration.

-

Using an incorrectly sized meter may result in skewed flow readings.

2. Know Your Pipe’s Inner Diameter (ID)

Your first step is to determine the inner diameter (ID) of your pipe—not just the nominal pipe size (NPS). While many pipe sizes are standardized (e.g., 4-inch, 6-inch), the ID can vary based on material and schedule.

For example:

-

A 6” Schedule 40 steel pipe has an ID of 6.065″

-

A 6” Schedule 80 pipe has an ID of 5.761″

These small differences can significantly impact flow velocity and meter calibration.

🛠️ Pro Tip: Use calipers or consult piping specifications to get the exact ID.

3. Understand the Minimum and Maximum Flow Range for Your Pipe Size

The ideal velocity range for most insertion flow meters is between 0.3 m/s to 10 m/s. Outside this range, accuracy may drop.

To determine your expected velocity:

Once you know your expected flow velocity, ensure it’s within the operating range of the insertion meter you’re considering.

4. Consider Pipe Material and Wall Thickness

Different pipe materials have different strengths and installation requirements:

-

PVC or HDPE: Easy to drill but can deform, so mounting kits must ensure a tight seal.

-

Carbon steel or stainless steel: Require hot tapping tools or welding saddles.

-

Concrete or lined pipes: May need special anchors or sleeves.

Also, wall thickness affects the length of the insertion probe. If it’s too short, it may not reach the center of the pipe where optimal readings occur.

5. Match Probe Length to Pipe Diameter

Most insertion meters are designed with standard probe lengths (e.g., 100mm, 200mm, 400mm), and the probe should reach at least ⅛ to ¼ of the pipe diameter into the flow to ensure accurate velocity sampling.

For example:

-

For a 12-inch pipe (300 mm ID), choose a 150 mm or longer probe.

-

For a 4-inch pipe (100 mm ID), a 100 mm probe may be sufficient.

Undersized probes can lead to poor signal strength and measurement errors.

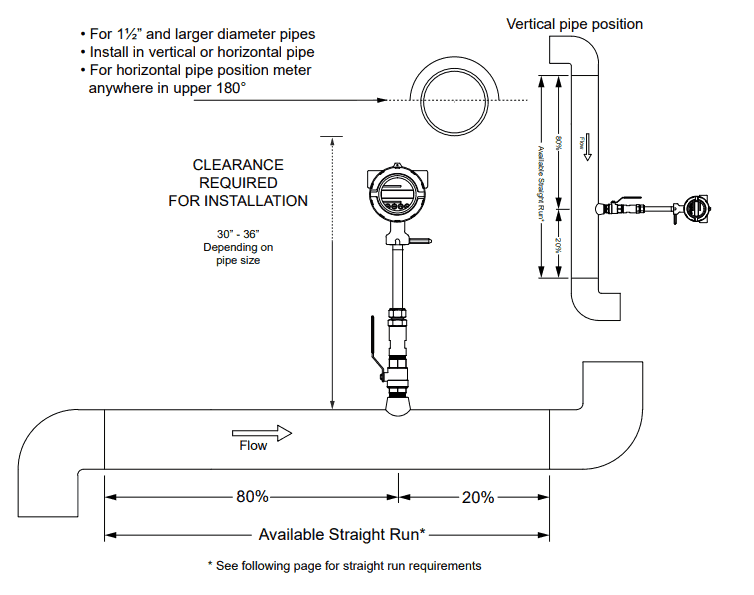

6. Check the Available Straight Pipe Length

To achieve laminar flow conditions, flow meters typically require straight runs of pipe upstream and downstream of the sensor:

-

10D upstream (10× pipe diameter)

-

5D downstream

If you’re short on space, look for flow meters with flow profile compensation or multi-point sensors.

7. Determine the Installation Method

Your pipe size and system constraints will affect how you install the meter:

-

Small to mid-size pipes (up to 12 inches): Standard compression fittings or threaded mounting may be used.

-

Large pipes (over 12 inches): Typically require hot tapping or weld-on saddles.

-

Pressurized systems: Require hot tap insertion with valve assemblies to avoid shutdowns.

Some insertion meters come with hot tap kits, allowing installation without interrupting flow.

8. Choose the Right Flow Meter Technology Based on Pipe Size

Insertion flow meters come in various technologies:

a. Electromagnetic (Magmeters):

-

Great for conductive liquids.

-

Require full contact with the liquid.

-

Performance varies with pipe diameter and flow profile.

b. Thermal Mass Flow Meters:

-

Ideal for gases in HVAC or industrial systems.

-

Accuracy depends on sensor placement and cross-sectional velocity.

c. Ultrasonic (Transit-Time or Doppler):

-

Works well with clean or dirty fluids.

-

Sensor insertion depth must match the acoustic focus for the pipe size.

Each technology performs differently at various pipe diameters. Check manufacturer recommendations.

9. Don’t Ignore Operating Pressure and Temperature

The larger the pipe, the more critical it becomes to account for pressure class and thermal expansion:

-

Ensure the insertion meter’s mounting hardware is rated for your system pressure.

-

Larger pipes are more prone to temperature-induced expansion, which can affect seal integrity.

-

Verify that O-rings and sealing materials are compatible with your temperature range.

Neglecting this step could lead to leaks, signal loss, or even system damage.

10. Review Accuracy and Calibration Options by Pipe Size

Larger diameter pipes often require field calibration due to complex flow profiles. Ask the vendor:

-

Is the flow meter factory calibrated for your specific pipe size?

-

Can you perform on-site calibration using a reference method?

-

Is dual-point or multi-point sensing available for larger pipes?

Larger pipes = more turbulence = higher potential for error, so advanced calibration is a must.

11. Don’t Forget Compliance and Certifications

For pipes carrying potable water, wastewater, or chemicals, compliance is key. Look for:

-

NSF certifications for drinking water

-

CE or RoHS compliance for international standards

-

ATEX / IECEx for hazardous environments

Also, check if the meter model is approved for your industry—water utilities, food & beverage, chemical, etc.

12. Get Expert Help for Custom or Large-Diameter Pipes

When dealing with pipe diameters greater than 24 inches, or non-standard piping systems, it’s best to:

-

Request a custom recommendation from the manufacturer

-

Use flow modeling software to simulate insertion depth and flow profiles

-

Consider multi-point insertion meters for enhanced accuracy

Many brands offer technical support teams or installation consulting—take advantage of it.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument