Choosing the right electrode for an insertable electromagnetic flowmeter isn’t just a minor technical detail—it’s a critical decision that impacts measurement accuracy, operational lifespan, and overall system reliability. Whether you’re in water treatment, chemical processing, mining, or manufacturing, understanding how to select the proper electrode material can make the difference between efficient operation and costly downtime.

In this comprehensive guide, we’ll walk you through everything you need to know about selecting electrodes for insertable electromagnetic flowmeters—from material characteristics to application-based recommendations—so you can make the best-informed choice for your specific process.

The Role of Electrodes in Electromagnetic Flowmeters

In an electromagnetic flowmeter, the electrodes are the sensing elements that detect the induced voltage as the conductive fluid moves through the magnetic field. This voltage is directly proportional to the fluid’s flow velocity.

Since electrodes are in direct contact with the process fluid, they must possess the following properties:

-

High electrical conductivity

-

Excellent chemical resistance

-

Resistance to abrasion and corrosion

-

Thermal stability for high-temperature applications

Choosing the right electrode material is not optional—it’s essential to maintain accurate readings and prolong equipment life.

Why Electrode Material Selection Matters

Different applications involve different process fluids, temperatures, pressures, and flow conditions. Selecting an unsuitable electrode material may lead to:

-

Corrosion or pitting of the electrode surface

-

Measurement drift or signal degradation

-

Sensor failure and expensive downtime

-

Frequent maintenance or calibration issues

In other words, electrode material isn’t just a matter of cost—it’s about matching chemistry and application conditions to ensure reliability and longevity.

Common Electrode Materials and Their Properties

Let’s break down the most widely used electrode materials, their characteristics, and their typical applications:

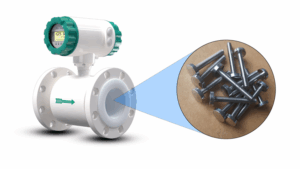

1. 316L Stainless Steel

Properties:

-

Good corrosion resistance to water and mildly acidic/basic solutions

-

Economical and widely available

Best suited for:

-

Potable water

-

Cooling water

-

Industrial wastewater

Limitations:

-

Poor resistance to strong acids, chlorides, and abrasive slurries

2. Hastelloy B

Properties:

-

Excellent resistance to reducing acids like hydrochloric acid

-

Good thermal stability

Best suited for:

-

Chloride-containing environments

-

Organic acid processes

Limitations:

-

Less effective in oxidizing media such as nitric acid

3. Hastelloy C

Properties:

-

Resistant to both reducing and oxidizing chemicals

-

Handles aggressive agents like chlorine and nitric acid

Best suited for:

-

Harsh chemical processing environments

-

Mixed acid systems

Limitations:

-

Higher cost compared to stainless steel and Hastelloy B

4. Titanium

Properties:

-

Outstanding resistance to seawater and wet chlorine gas

-

Forms a protective oxide film that resists corrosion

Best suited for:

-

Saltwater

-

Chloride-rich industrial processes

Limitations:

-

Not ideal for strong acids such as sulfuric acid

5. Tantalum

Properties:

-

Exceptional resistance to nearly all acids (including nitric, sulfuric, and hydrochloric acids)

-

Similar corrosion resistance to glass or ceramic

Best suited for:

-

Highly aggressive chemicals

-

Pharmaceuticals and fine chemicals

Limitations:

-

Extremely expensive

-

Can be mechanically fragile in high-flow systems

6. Platinum-Iridium Alloy

Properties:

-

Inert to nearly all chemicals

-

Excellent high-temperature stability

Best suited for:

-

Laboratory-grade accuracy

-

Harsh mixed-acid environments

Limitations:

-

Prohibitively expensive for most industrial applications

Matching Electrode Materials with Process Conditions

Choosing the right electrode starts with evaluating your process parameters. Ask the following questions:

1. What is the fluid composition?

-

Pure water? → Stainless steel or titanium

-

Acidic wastewater? → Hastelloy C or tantalum

-

Chloride-rich fluid? → Titanium or Hastelloy B

2. What is the pH range?

-

Neutral (pH 6–8): Most materials will suffice

-

Highly acidic or basic: Go with chemically resistant alloys

3. Is the fluid abrasive?

-

Yes → Use hardened alloys or coated electrodes

-

No → Standard materials may be acceptable

4. What are the temperature and pressure levels?

-

High temperatures may require platinum or Hastelloy

-

High pressure environments demand structurally strong materials

Application-Based Electrode Recommendations

Here’s a quick-reference table to guide your material selection based on common applications:

| Application | Recommended Electrode | Notes |

|---|---|---|

| Drinking Water | 316L Stainless Steel | Economical and sufficient corrosion resistance |

| Seawater | Titanium | Excellent chloride resistance |

| Chlorinated Water | Hastelloy C or Titanium | Withstands oxidative agents |

| Wastewater with Sulfides | Hastelloy B | Handles reducing environments |

| Mixed Acids (e.g., Nitric + HCl) | Tantalum or Hastelloy C | Extreme corrosion resistance |

| Pharma or Food Applications | Platinum-Iridium or Tantalum | High purity and stability |

Conclusion: Electrode Choice Is Not Optional—It’s Foundational

Choosing the appropriate electrode for an insertable electromagnetic flowmeter is more than a technical formality—it’s a strategic decision. With the wide variety of fluid types, chemical properties, temperatures, and flow conditions in industrial systems, your electrode material must be tailored to your application.

By understanding:

-

The role of electrode materials

-

How they interact with different fluids

-

When to invest in premium alloys

…you can ensure maximum reliability, optimal performance, and lower maintenance costs over the life of your flowmeter.

Remember: The right electrode makes all the difference. Don’t treat it as an afterthought—make it your first priority.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument