Wastewater treatment is a complex, high-stakes operation where accurate and reliable flow measurement is critical. Among the many flowmeter options available, insertion type electromagnetic flowmeters have emerged as a preferred solution, especially in large pipelines or retrofitting existing systems. If you’re an engineer, plant manager, or procurement officer exploring the best tools for water and wastewater applications, this comprehensive guide will equip you with everything you need to know.

In this in-depth article, we’ll cover:

What is an Insertion Type Electromagnetic Flowmeter?

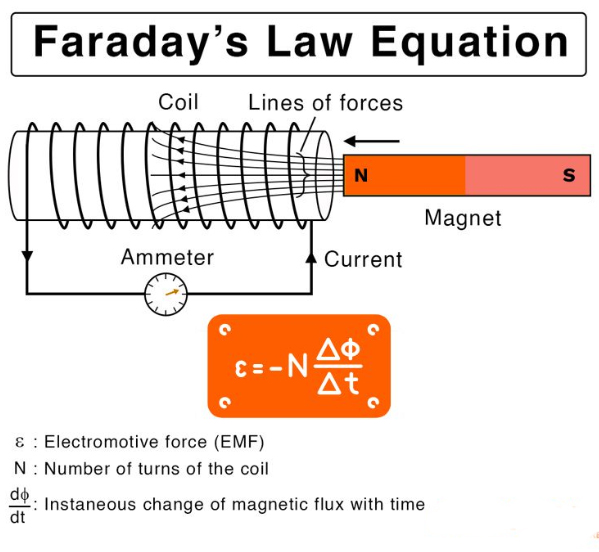

An insertion electromagnetic flowmeter, often referred to as an insertion mag meter, is a flow measurement device that uses Faraday’s Law of Electromagnetic Induction to measure the flow rate of conductive liquids.

Unlike full-bore mag meters, which require a dedicated spool piece installed into the pipeline, insertion flowmeters are inserted into the pipe wall and typically measure velocity at a specific point or average it across multiple depths.

This design makes them cost-effective and minimally invasive, especially for large-diameter pipelines commonly found in wastewater treatment plants.

How Does It Work?

The principle behind the insertion mag meter is relatively straightforward. According to Faraday’s Law, when a conductive liquid flows through a magnetic field, a voltage is generated perpendicular to the flow direction.

Key Components:

-

Electrodes: Positioned within the flow tube to capture induced voltage.

-

Magnetic field generator: Creates a stable magnetic field.

-

Electronics module: Interprets voltage as a flow rate and outputs a signal.

In insertion mag meters, the probe containing electrodes is inserted into the pipe, typically reaching the center of the flow. The signal measured is proportional to the fluid’s velocity, and the electronics use pipe diameter data to calculate volumetric flow.

Why Insertion Mag Meters Are Ideal for Wastewater Treatment

1. Cost-Effective for Large Pipes

In large pipelines (e.g., DN300 and above), full-bore electromagnetic flowmeters can be prohibitively expensive. Insertion-type designs slash hardware and installation costs, making them ideal for budget-conscious municipalities and industrial operations.

2. Non-Obstructive and Low Pressure Drop

Insertion mag meters do not introduce moving parts or significant obstruction into the flow. This is especially critical in wastewater streams, where solids and debris can clog traditional flowmeters like turbines or paddlewheels.

3. Resistant to Corrosion and Fouling

Many wastewater fluids contain aggressive chemicals, suspended solids, and corrosive substances. Insertion mag meters can be equipped with chemical-resistant linings and electrodes, ensuring long-term performance.

4. Easy Retrofitting

Because they don’t require full pipe removal, insertion meters are easy to install on existing lines, minimizing downtime and civil work. This makes them popular in plant upgrades and compliance monitoring projects.

Insertion Mag Meter vs. Full-Bore Mag Meter

| Feature | Insertion Mag Meter | Full-Bore Mag Meter |

|---|---|---|

| Installation | Through a tap in the pipe wall | Requires pipe cutting and flanged connection |

| Cost | Lower for large pipes | Higher, especially with increasing pipe size |

| Accuracy | Moderate to high (±1.0–2.0%) | High (±0.5% or better) |

| Maintenance | Can be removed without line shutdown | Usually requires shutdown for maintenance |

| Best suited for | Large pipes, retrofit, cost-sensitive apps | High-accuracy, small-to-medium pipelines |

Applications in Wastewater Treatment

Insertion electromagnetic flowmeters are widely used in both municipal and industrial wastewater applications, including:

-

Influent and effluent flow measurement

-

Sludge and return activated sludge (RAS) lines

-

Chemical dosing and pH control

-

Bypass and overflow monitoring

-

Stormwater and combined sewer systems

Their versatility and durability make them ideal for continuous monitoring, batch control, and compliance reporting.

Installation Considerations

While insertion meters are simpler to install, some best practices ensure accurate and reliable measurements:

1. Straight Pipe Length

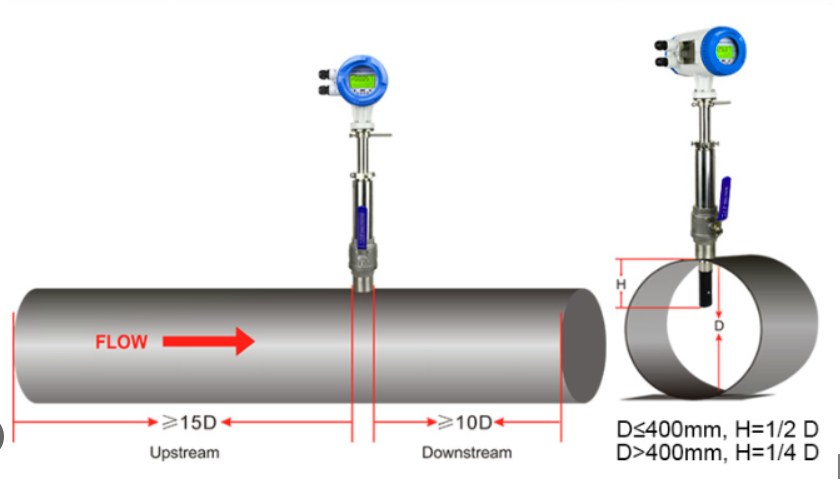

Maintain sufficient upstream and downstream straight pipe runs—typically 15D upstream and 10D downstream (where D = pipe diameter).

2. Proper Insertion Depth

The probe must reach the center of the flow stream for single-point velocity measurement. Some models offer multi-point or averaging probes for improved accuracy.

3. Isolation Valves

Use a ball or gate valve for hot-tap installations, allowing for probe insertion/removal without stopping the flow.

4. Electrical Grounding

Since electromagnetic flowmeters are sensitive to stray voltage, proper grounding rings and wiring are essential.

Materials, Liners, and Electrode Options

Material compatibility is crucial in wastewater applications. Here’s a breakdown of popular choices:

-

Electrode Materials:

-

316L stainless steel – common and cost-effective

-

Hastelloy C – highly corrosion-resistant

-

Titanium or Tantalum – for extreme chemicals

-

-

Liners or Sensor Housings:

-

PTFE

-

Choose materials based on fluid pH, temperature, abrasiveness, and chemical content.

Accuracy and Calibration

Insertion mag meters typically offer accuracy between ±1.0% and ±1.5% of reading, which is suitable for most wastewater applications. However, installation alignment, flow profile, and air bubbles can impact measurement precision.

To maintain accuracy:

-

Calibrate the meter periodically, especially in regulated environments.

-

Use flow simulators or verification tools for in-situ calibration if available.

Maintenance Best Practices

Insertion meters are generally low-maintenance, but routine checks can extend their lifespan:

-

Inspect and clean the probe regularly, especially in sludge or sediment-rich environments.

-

Check grounding and electrical connections periodically.

-

Monitor signal stability and alarm outputs from the transmitter.

-

Replace worn O-rings, seals, or electrodes as needed.

Some advanced models offer self-diagnostics and remote condition monitoring, reducing the need for manual intervention.

How to Choose the Right Insertion Electromagnetic Flowmeter

When selecting an insertion mag meter for wastewater treatment, consider:

-

Pipe size and material

-

Flow range and accuracy needs

-

Fluid composition (chemical, solid content, temperature)

-

Installation constraints (e.g., available straight run, access)

-

Signal output (4–20mA, pulse, Modbus, HART, etc.)

-

Certifications (e.g., ISO, CE, RoHS, ATEX if applicable)

Also evaluate supplier support, warranty, and integration with SCADA or DCS systems.

Conclusion

Insertion-type electromagnetic flowmeters are a game-changer for wastewater treatment. Their combination of cost-efficiency, easy installation, and dependable performance makes them ideal for measuring flows in complex, large-scale, or retrofit applications.

Whether you’re dealing with industrial effluent, municipal sewage, or stormwater, these flowmeters deliver accurate, real-time insights that are essential for compliance, process optimization, and sustainability.

Choose wisely, install correctly, and maintain proactively—and your insertion mag meter will be a reliable asset in your water management toolkit for years to come.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument