When it comes to measuring fluid flow, accuracy, reliability, and efficiency are non-negotiable. Industries ranging from oil and gas to food and beverage rely heavily on flow measurement technologies to maintain quality control, optimize production, and ensure safety. Among these technologies, the turbine flowmeter stands out as a popular choice. But with alternatives such as electromagnetic, ultrasonic, Coriolis, vortex, and differential pressure flowmeters available, many engineers and plant operators are left asking: Which flow technology is truly the best?

In this article, we’ll dive deep into turbine flowmeters and compare them with other leading flow measurement methods. By the end, you’ll have a clear understanding of their strengths, weaknesses, and the best-fit applications for each.

Advantages of Turbine Flowmeters

Turbine flowmeters continue to be a go-to choice for many industries thanks to their unique benefits:

-

High accuracy for custody transfer applications

-

Low pressure drop, meaning less energy loss in the system

-

Wide operating range, handling both low and high flow rates

-

Proven reliability with decades of industrial use

-

Cost-effectiveness compared to advanced technologies like Coriolis

Limitations of Turbine Flowmeters

Despite their strengths, turbine flowmeters are not suitable for every situation. Their drawbacks include:

-

Not ideal for dirty or abrasive fluids (particles can damage the rotor)

-

Wear and tear on moving parts leads to higher maintenance

-

Sensitivity to viscosity changes, reducing accuracy with thicker fluids

-

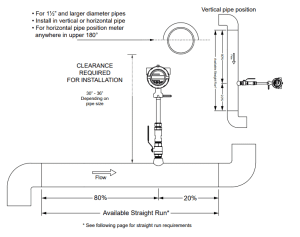

Installation orientation matters, as improper alignment may affect performance

Competing Flow Technologies at a Glance

Before declaring a “winner,” let’s briefly explore other leading flow measurement technologies:

-

Electromagnetic Flowmeters (Magmeters) – Use Faraday’s law to measure conductive liquids.

-

Ultrasonic Flowmeters – Employ sound waves to measure velocity in clean or dirty fluids.

-

Coriolis Flowmeters – Directly measure mass flow and density with vibrating tubes.

-

Vortex Flowmeters – Detect vortices shed by a bluff body in the fluid stream.

-

Differential Pressure (DP) Flowmeters – Measure pressure drop across an orifice plate, venturi, or nozzle.

Each has distinct advantages and trade-offs depending on the application.

Turbine Flowmeter vs. Electromagnetic Flowmeter

Magmeters have no moving parts and excel in measuring conductive liquids such as wastewater, slurries, and corrosive chemicals.

-

Accuracy: Comparable to turbine flowmeters (±0.2% to ±0.5%).

-

Durability: Better, since no moving parts.

-

Limitation: Cannot measure non-conductive fluids like oils or hydrocarbons.

Winner: Use turbine for hydrocarbons, magmeter for water-based fluids.

Turbine Flowmeter vs. Ultrasonic Flowmeter

Ultrasonic meters use transit-time or Doppler signals. They are highly versatile and can even be clamp-on for non-invasive measurements.

-

Accuracy: ±0.5% to ±2%, depending on type.

-

Maintenance: Minimal, as no moving parts.

-

Limitation: Accuracy depends on fluid cleanliness and pipe conditions.

Winner: Ultrasonic wins in non-invasive and large pipe applications; turbine wins for compact, accurate liquid measurement.

Turbine Flowmeter vs. Coriolis Flowmeter

Coriolis meters directly measure mass flow and density, making them extremely accurate (±0.1%).

-

Accuracy: Superior to turbine.

-

Versatility: Works for liquids, gases, and slurries.

-

Limitation: Very expensive and often larger/heavier.

Winner: Coriolis for high-value custody transfer; turbine for cost-effective accuracy.

Turbine Flowmeter vs. Vortex Flowmeter

Vortex meters detect oscillating vortices created by a bluff body in the flow. They are popular in steam, gas, and liquid measurement.

-

Accuracy: ±0.5% to ±1%.

-

Durability: Excellent, no moving parts.

-

Limitation: Less effective in low flow rates.

Winner: Vortex for steam and gas; turbine for low-flow liquids.

Turbine Flowmeter vs. Differential Pressure Flowmeter

DP meters are traditional, widely used, and cost-effective. They measure flow by the pressure drop across an obstruction.

-

Accuracy: Typically ±1% to ±2%.

-

Durability: Good, but requires pressure taps and can clog.

-

Limitation: Significant pressure loss and higher energy costs.

Winner: Turbine for higher accuracy and efficiency; DP for simple, low-cost systems.

Choosing the Right Flowmeter for Your Application

Selecting a flowmeter is not about picking the most advanced technology—it’s about matching the technology to the process requirements. Key factors to consider include:

-

Fluid type (clean, dirty, conductive, viscous, or gaseous)

-

Accuracy requirements (custody transfer vs. process monitoring)

-

Operating conditions (temperature, pressure, pipe size)

-

Budget (initial cost vs. lifecycle maintenance)

-

Regulatory standards (industry-specific compliance)

Future Trends in Flow Measurement Technology

Flowmeter technology is evolving with digitalization, IoT integration, and predictive maintenance. Modern turbine flowmeters are now paired with smart electronics for real-time monitoring, wireless data transmission, and improved diagnostics. Meanwhile, newer alternatives like Coriolis and ultrasonic are gaining traction in industries prioritizing precision and automation.

Conclusion

So, which flow technology wins? The answer depends on the application.

-

Choose turbine flowmeters when you need cost-effective, highly accurate liquid measurement for clean, low-viscosity fluids.

-

Opt for magmeters for conductive liquids, ultrasonic for non-invasive measurements, Coriolis for mass flow accuracy, vortex for steam and gases, and DP meters for budget-conscious applications.

Ultimately, there is no one-size-fits-all winner—but turbine flowmeters remain a trusted, reliable, and efficient choice across multiple industries.