1. Understanding Insertion Flow Meters

Insertion flow meters are devices designed to measure the flow rate of liquids or gases by inserting a sensor into the flow stream. Unlike full-bore flow meters, which require a section of pipe to be removed or bypassed, insertion meters are installed directly into the pipeline, making them ideal for retrofit projects or where space is limited.Key benefits of insertion flow meters include:- Ease of installation

- Cost-effective?for large pipe diameters

- Minimal disruption?during setup

- Suitable for?wide range of liquids and gases

2. Electromagnetic Insertion Flow Meters

How They Work

Electromagnetic flow meters, or mag meters, operate based on Faraday¡¯s Law of electromagnetic induction. When a conductive fluid passes through a magnetic field generated by coils in the sensor, it induces a voltage proportional to the flow velocity. The insertion electromagnetic flow meter has a magnetic coil and electrodes inserted into the pipeline.Advantages

- High accuracy?for conductive fluids

- Reliable measurement?over a wide range of flow rates

- Low maintenance?due to no moving parts

- Suitable for?dirty or slurry fluids

Limitations

- Only works with?conductive liquids?(water, wastewater, some chemicals)

- Susceptible to?electrical noise?interference

- Requires?power supply?for operation

Best Use Cases

- Water treatment plants

- Industrial effluent monitoring

- Chemical processing where the fluid is conductive

3. Ultrasonic Insertion Flow Meters

How They Work

Ultrasonic insertion flow meters utilize high-frequency sound waves to measure flow velocity. The sensor emits ultrasonic signals across the pipe, and the difference in transit time between upstream and downstream signals helps determine flow rate.Advantages

- Non-intrusive?with no contact with the fluid (depending on the model)

- Compatible with?clean?and?partially contaminated?fluids

- Suitable for?large pipe diameters

- No moving parts, hence?low maintenance

Limitations

- Less effective with?highly turbulent?or?dirty fluids

- Requires?proper calibration?for accuracy

- Can be?more expensive?initially

Best Use Cases

- Oil and gas pipelines

- Water and wastewater applications

- Food and beverage industries with clean fluids

4. Vortex Insertion Flow Meters

How They Work

Vortex flow meters measure flow by detecting the vortices shed by a bluff body placed in the flow stream. The frequency of vortex shedding correlates directly with flow velocity, which the meter converts into a flow rate.Advantages

- Robust and durable

- Suitable for?wide temperature?and?pressure ranges

- Can handle?slurries, gases, and liquids

- Low power consumption

Limitations

- Lower accuracy?at very low flow rates

- Sensitive to?fluid turbulence?and?swirl

- Slightly more complex installation compared to other insertion types

Best Use Cases

- Steam, gas, and liquid flow measurement

- Industries requiring?high durability, such as petrochemical plants

- Applications involving?dirty or abrasive fluids

5. Comparing Accuracy and Precision

| Feature | Electromagnetic | Ultrasonic | Vortex |

|---|---|---|---|

| Accuracy | High (for conductive fluids) | Moderate | Moderate to high (depending on conditions) |

| Best for | Conductive liquids | Clean or slightly contaminated fluids | Wide range, including gases and slurries |

6. Installation and Maintenance Considerations

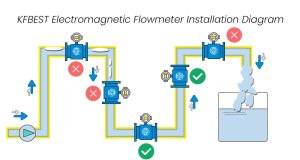

Ease of installation can significantly impact project timelines and costs.- Electromagnetic meters?require?pipe sections?that are conductive and may need electrical grounding.

- Ultrasonic meters?can be inserted into existing pipes with minimal disruption, especially non-contact types.

- Vortex meters?demand a?straight flow section?for accurate readings, which might require pipe modifications.

- Electromagnetic meters are?low maintenance?but need?power supply.

- Ultrasonic meters are?virtually maintenance-free?but require?clean sensors.

- Vortex meters involve?moving bluff bodies, which may need periodic inspection or cleaning.

7. Cost Analysis: Which Flow Meter Fits Your Budget?

Initial costs, installation expenses, and long-term maintenance influence the total cost of ownership.- Electromagnetic flow meters?tend to be?more expensive?initially but offer?high accuracy?and durability.

- Ultrasonic flow meters?can be?cost-effective?for large-scale or retrofit projects.

- Vortex flow meters?offer a?balance of affordability and durability, especially in demanding environments.

8. Environmental and Operational Factors

Your environment plays a pivotal role in selecting the right flow meter:- Electrical interference?favors ultrasonic meters over electromagnetic types.

- Aggressive chemicals?or?abrasive solids?may limit the lifespan of certain sensors.

- Temperature and pressure?variations should align with the manufacturer’s specifications.

- Flow turbulence?can affect vortex meters, leading to less reliable readings.

9. Which Insertion Flow Meter Should You Choose?

Choosing the ideal insertion flow meter hinges on the specific application:- Opt for?Electromagnetic Insertion Flow Meters?if your fluid is?conductive, and?accuracy?is paramount.

- Select?Ultrasonic Insertion Flow Meters?for?non-conductive fluids?or?clean water applications?where?non-intrusive measurement?is desired.

- Consider?Vortex Insertion Flow Meters?for?harsh environments,?gases, or?slurries?where robustness is critical.

10. Final Thoughts and Recommendations

In summary, the decision about which insertion flow meter to purchase should be based on a careful assessment of your specific needs, including fluid type, flow conditions, accuracy requirements, and budget constraints. Each model discussed has unique strengths and limitations:- Electromagnetic?meters excel with?conductive liquids?and demand?high accuracy.

- Ultrasonic?meters are ideal for?clean fluids?and?non-intrusive measurements.

- Vortex?meters are?durable?and?versatile, suitable for?demanding industrial environments.

Conclusion

Choosing the right insertion flow meter is a crucial decision that impacts your operational efficiency and measurement accuracy. By understanding the working principles, advantages, limitations, and best-use scenarios of electromagnetic, ultrasonic, and vortex insertion flow meters, you can confidently select a model tailored to your application. Remember, the right flow meter not only provides accurate data but also enhances safety, reduces downtime, and improves overall process performance. Make an informed choice today for a more efficient tomorrow!We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument