To?ensure?that?the?electromagnetic?flowmeter?functions?well?and?lasts?as?long?as?possible,?follow?the?manufacturer’s?installation?and?maintenance?instructions?exactly.?In?this?blog,?we?will?look?at?the?key?aspects?of?installing?flowmeters,?focusing?on?three?primary?areas:?piping?design,?sensor?placement,?and?machinery?configuration.?Proper?installation?is?critical?to?ensuring?accurate?measurements?and?the?longevity?of?your?flowmeter?system.?Installing?electromagnetic?flowmeters?requires?careful?planning?to?ensure?accurate?operation?and?longevity. At?Best?Instrument,?we?understand?the?value?of?good?installation. Here?are?the?major?considerations:

1. Choosing the Installation Location

The positioning of your flowmeter is crucial for its efficient operation:

- Dry and Airy Spaces: Choose a location that is both dry and well-ventilated to prevent moisture gathering.

- Protection from the Environment: For outdoor installations, use protective covers to protect the meter from rain and sunshine.The recommended operating temperature range is between -20¡ãC and +60¡ãC.

- Avoiding Temperature Extremes: Keep the meter away from regions with extreme temperature fluctuations or intense thermal radiation. Insulation and enough airflow may be required to combat these situations.

- Avoid locations with corrosive gasses. If installation in such conditions is necessary, provide enough ventilation and use anti-corrosion methods.

- Vibration Reduction: Install the flowmeter away from sources of high vibration. If the pipe moves much, put fixed brackets on both sides to give stability.

- Choose flowmeters with adequate water resistance ratings, such as IP68 for immersion up to 3 meters or IP65 for non-water exposure.

2.Minimising Electromagnetic Interference

To maintain accurate measurements, keep the flowmeter away from electrical equipment, including motors, transformers, and converter distribution cabinets.

3. Ensure Proper Pipe Configuration.

Accurate flow measurement requires correct pipe alignment.

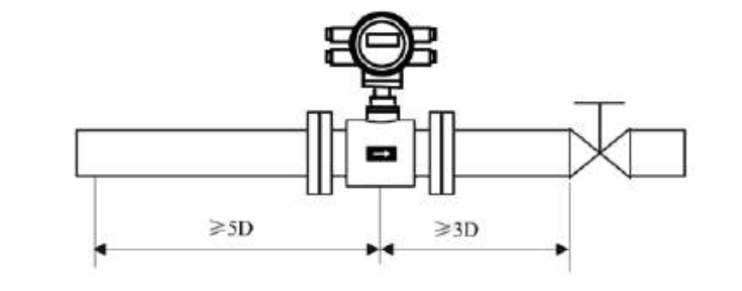

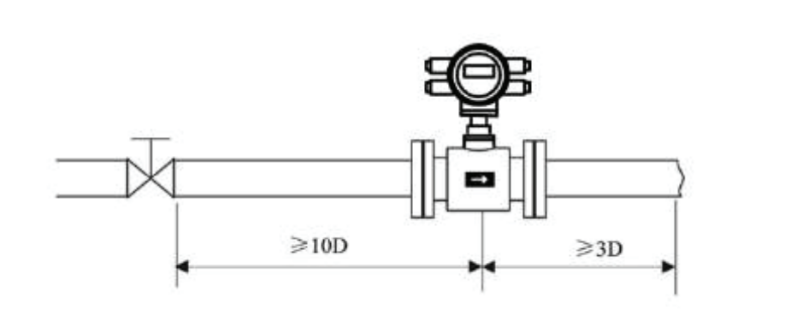

Straight Pipe Length: To improve accuracy, use at least five times the pipe diameter (5D) upstream and three times (3D) downstream of the sensor. This configuration helps to eliminate flow disruptions.

4. Providing Maintenance Space.

Ample space is critical for continuous maintenance:

Access to Maintenance: Make sure there is ample space around the flowmeter for easy installation and maintenance access.

5. Avoiding Flow Interruptions.

To ensure seamless operation:

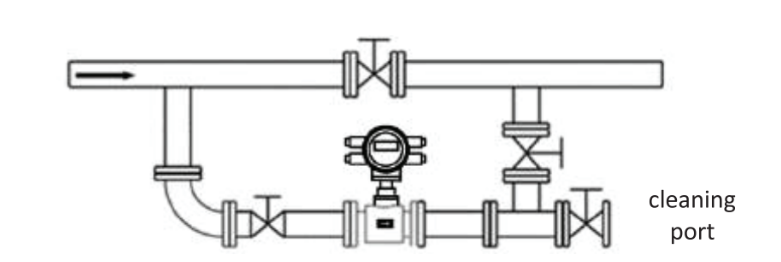

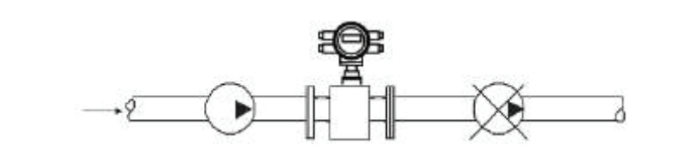

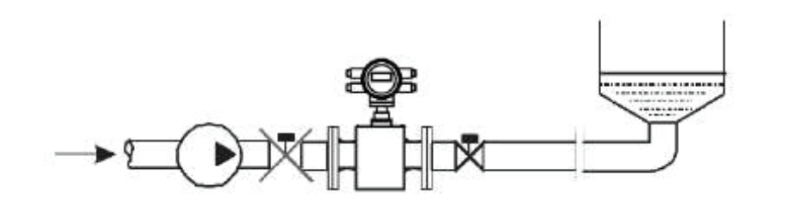

Bypass and Cleaning Ports: Add a bypass line and cleaning ports to your installation. This feature enables the system to continue operating even when the flowmeter requires maintenance.

6. Supporting the flowmeter.

Proper support is crucial to avoiding installation difficulties.

Stable Installation: Avoid attaching the flowmeter to pipes that are susceptible to free movements. Use a stable and secure base for the measurement pipe.If the flowmeter is installed underground, ensure that both the intake and output pipelines have supports, and consider placing protective metal plates above for added safety.

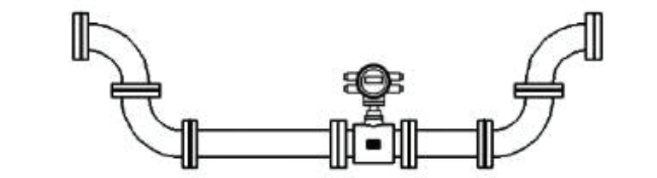

Straight pipe length requirements

The Connection which is easy to clean pipe

Installing Your Flowmeter: Ensuring Accurate Flow Direction Detection

When setting up your flowmeter, it is vital to configure it correctly for reliable functioning. A important characteristic of this flowmeter is its power to automatically recognize the flow direction, whether it is positive or negative.

Understanding Flow Direction

The manufacturer-designated positive flow direction is indicated by the flow arrow on the sensor enclosure. This arrow needs to line up with the real flow of your system in order to function at its best.

Installation Steps

Determine the Flow Direction: Determine the piping system’s flow direction before installation. To guarantee accurate measurements, this step is essential.

The arrow on the sensor housing should point in the direction of the process flow when you install the flowmeter. Accurate flow measurements depend on proper alignment.

Secure the Installation: Following alignment, confirm that the flowmeter is securely mounted while following any further instructions the manufacturer may have given for installation.

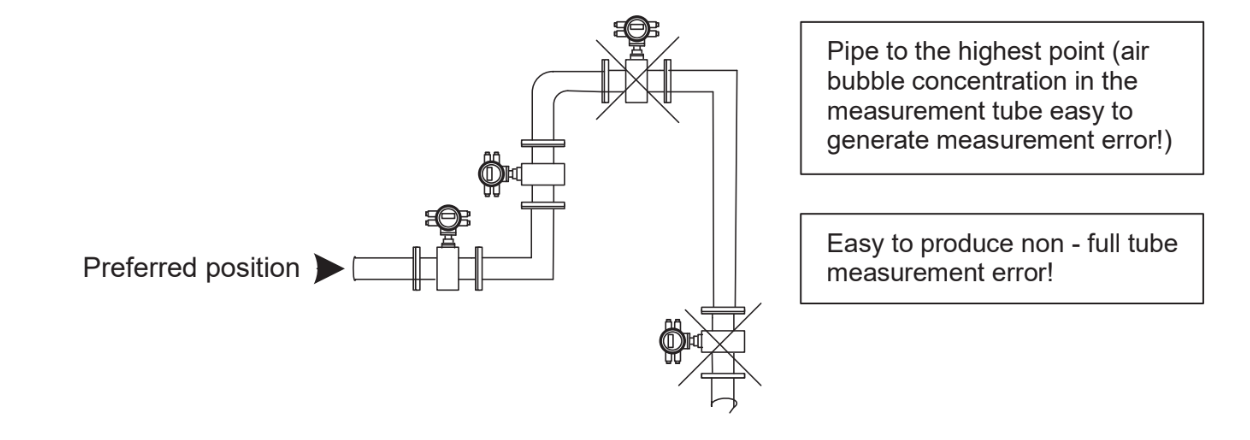

The ideal location for installing an electromagnetic flowmeter

Installation Orientation of Electromagnetic Flowmeters

When it comes to installing electromagnetic flowmeters, proper orientation is critical for accurate results. Sensors can be set up in either a horizontal or vertical position, but each technique has unique considerations:

Horizontal Installation

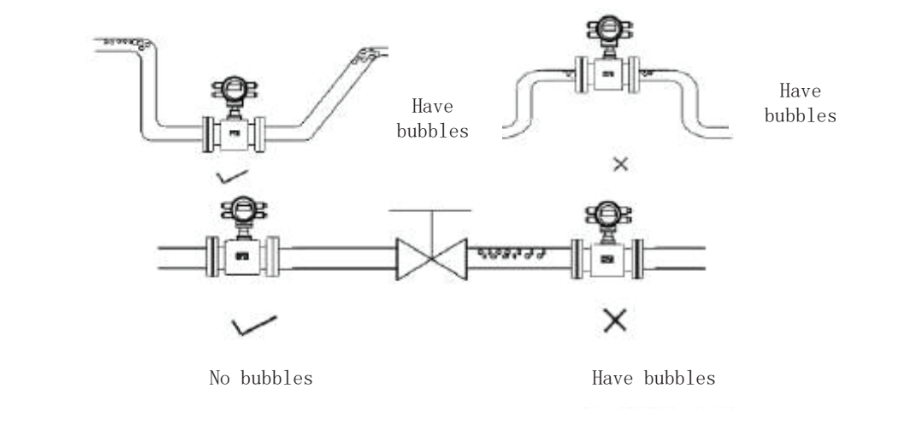

For horizontal installation, the electrodes must be positioned in a horizontal plane. This structure helps to avoid problems caused by bubbles or sediment buildup. By ensuring that bubbles do not form near the electrodes, you limit the possibility of zero drift and improve the signal dependability from the converter.

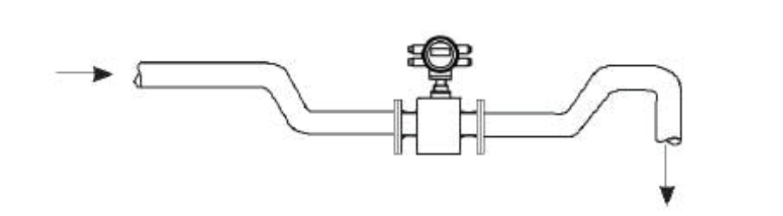

Vertical Installation

Vertical installations necessitate vertical electrode arrangement. This structure allows for rapid drainage of any bubbles or silt, which reduces interference in readings.

To prevent phase separation in a liquid containing solid particles or a slurry, place an electromagnetic flowmeter vertically. This configuration can help ensure even wear on the sensor from the second lining, as well as prevent three types of pollutants from accumulating at the bottom of the tube and going unmeasured.

It is critical to maintain a flow direction from bottom to top to guarantee that the sensor’s measuring tube is consistently filled with medium.

No bubbles in the pipe

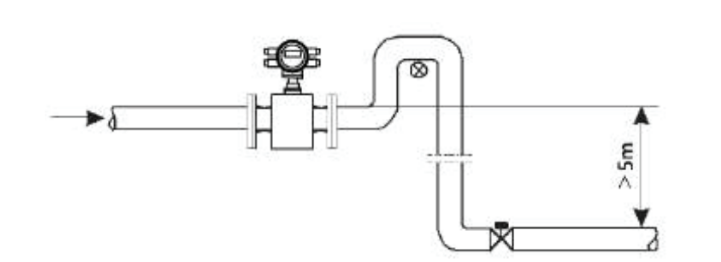

The design of the piping must ensure that gas does not separate from the liquid. It is essential to install the meter before the valve since the valve lowers the pressure in the pipe, which may lead to bubble formation. Additionally, instruments should be placed in the lower section to minimise the impact of entrained air bubbles on the measurements.

Machinery Installation: Key Guidelines for Flowmeter Setup

Installing the Flowmeter Pipe

Pipeline Calibration: The pipeline must be calibrated before the flowmeter is installed. Verify that the user’s pipeline and the flowmeter’s diameter match. The axis deviation on the high side should not exceed 1.5 mm for sensors with a nominal diameter of less than 50 mm. The maximum allowable variation for diameters between 65 and 300 mm is 2 mm, and for diameters of 350 mm or greater, it should not exceed 4 mm.

Cleaning the Pipeline: Remaining foreign contaminants, such as welding waste, are often present in recently constructed pipes. Cleaning away all impurities is essential before setting up the flowmeter. This procedure is required to guard against damage to the lining and to stop particles from entering the measuring tube while it is being used, which could lead to inaccurate measurements.

You?can?guarantee?your?electromagnetic?flowmeter’s?dependable?and?effective?operation?throughout?time?by?following?these?installation?instructions. Please?visit?our?website?or?send?an?email?to [email protected] with?any?inquiries. We?are?eager?to?help?you¡ªkeep?in?touch?with?Best?Instrument!