Type:industrial

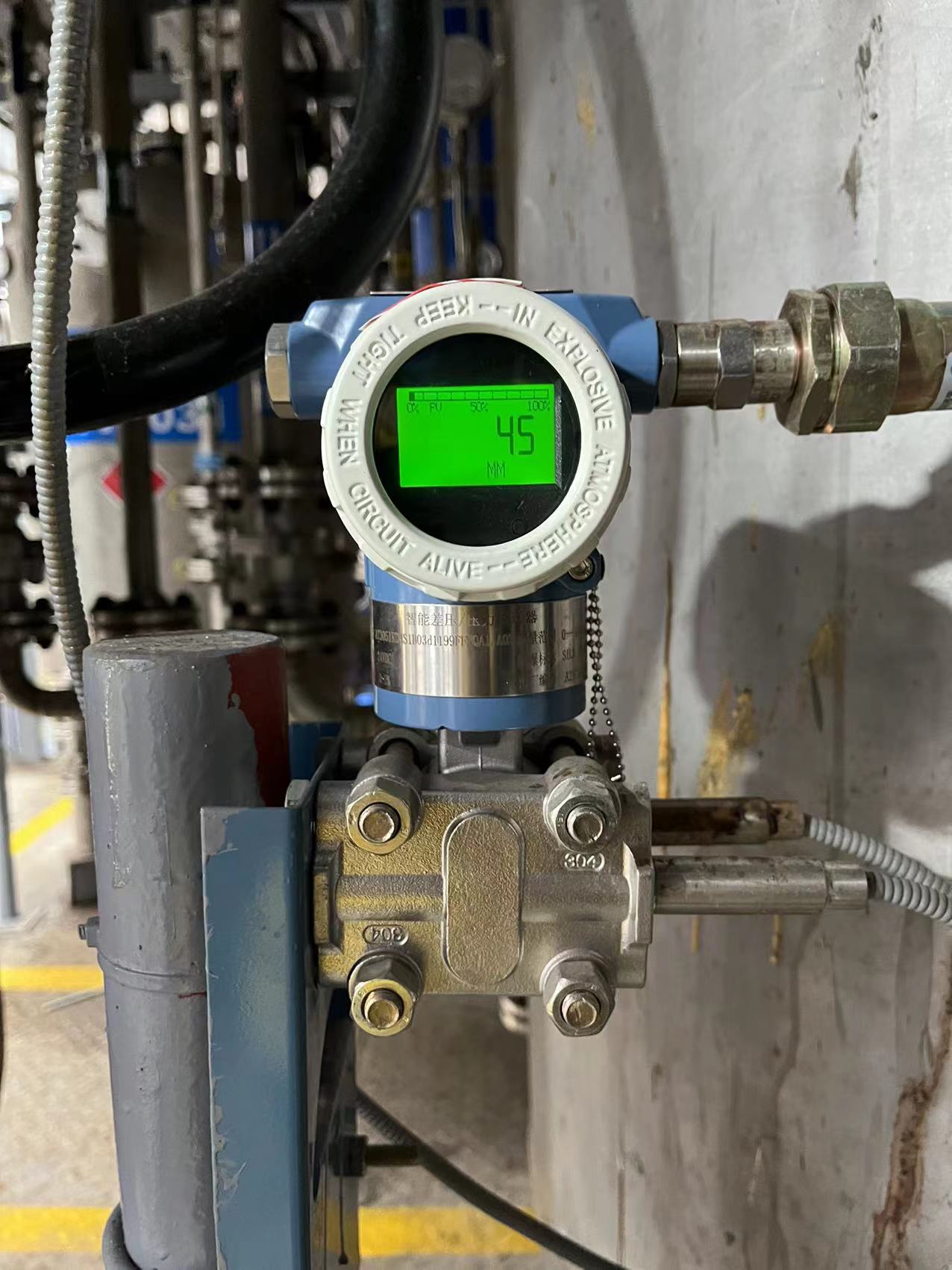

Ingress Protection:IP65

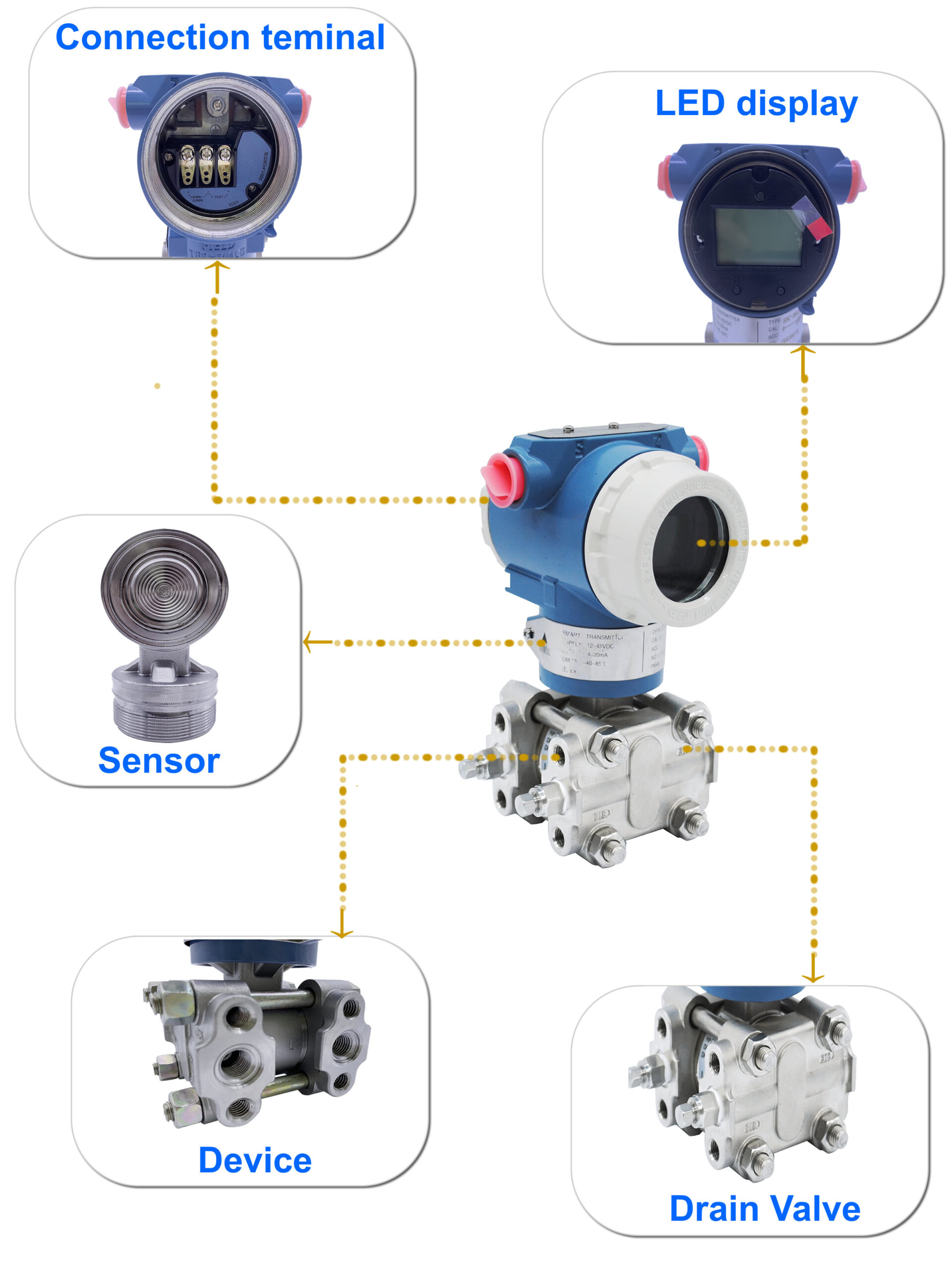

Model number:AT3051

Output Signal:4 – 20 mA 2 wires Hart Protocol

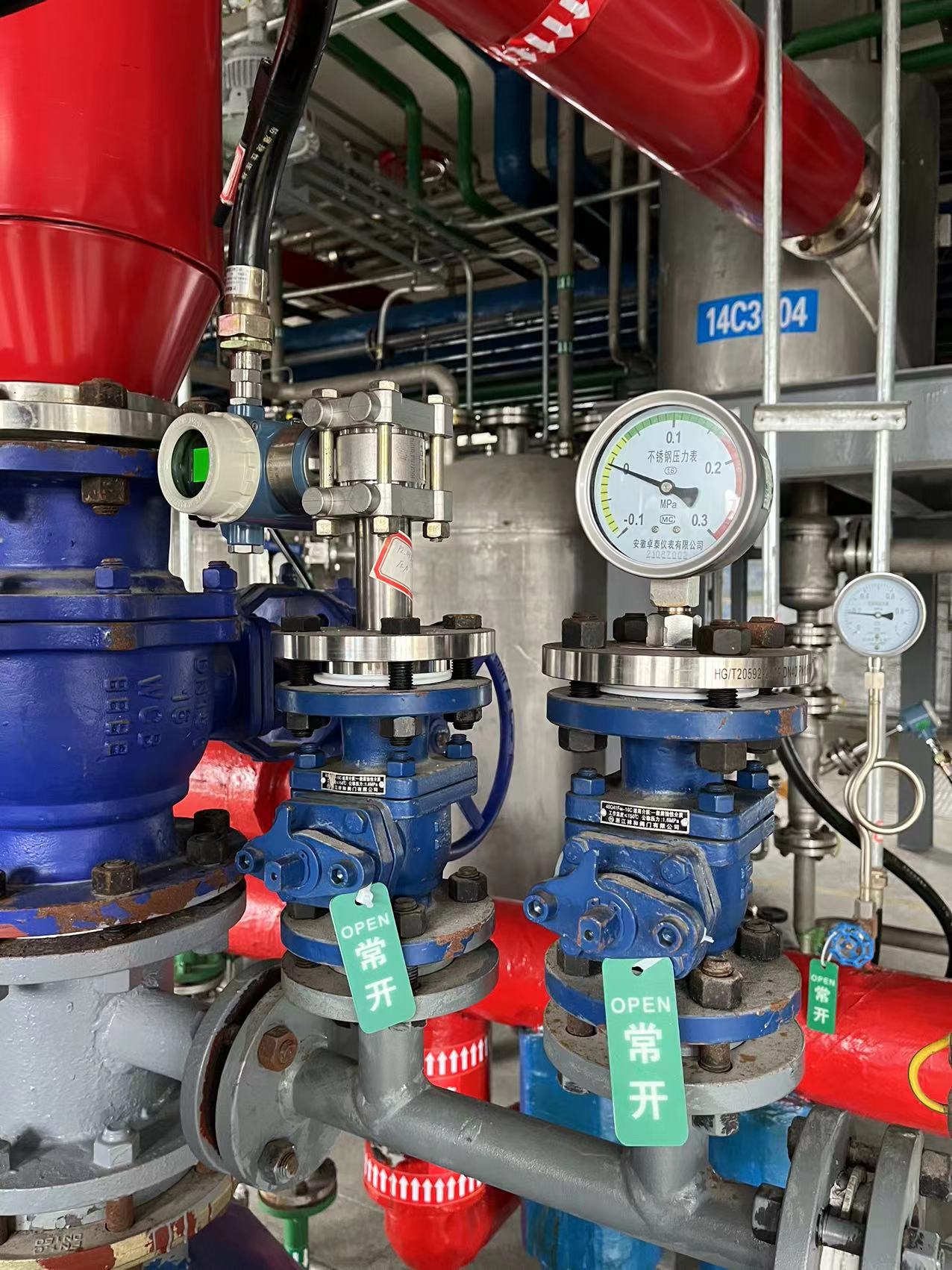

Application:Pressure Measurement

Medium:Liquid Gas Vapor

Protocol:HART

Operating Temperature: -40~+85℃

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument

|

Name

|

Specification code

|

Description

|

||||

|

AT3051GP

AT3051DP |

Pressure Transmitter

Differential Pressure Transmitter |

|||||

|

Measurement Range

|

2

|

0-0.1~1.5 Kpa

|

||||

|

3

|

0~7.5 Kpa

|

|||||

|

4

|

0~37.4 Kpa

|

|||||

|

5

|

0~186.8 Kpa

|

|||||

|

6

|

0~690 Kpa

|

|||||

|

7

|

0~2068 Kpa

|

|||||

|

8

|

0~6890 Kpa

|

|||||

|

9

|

0~20680 Kpa

|

|||||

|

Output

|

J

|

4-20mA, HART Protocol, Linear output

|

||||

|

S

|

4-20mA, HART Protocol, Square root output(Range≥5kpa)

|

|||||

|

Diaphragm Material / Fill Fluid

|

2

|

Stainless Steel 316L Silicone Oil

|

||||

|

3

|

Hastelloy C(range >3Kpa) Silicone Oi

|

|||||

|

A

|

Stainless Steel 316L Fluorine oil

|

|||||

|

Drain hole

|

B

|

Back of process flange or none

|

||||

|

U

|

Process flange side upper

|

|||||

|

L

|

Process flange side lower

|

|||||

|

Wetted O-ring Material

|

7

|

Buna-N (NBR)

|

||||

|

6

|

Viton (FKM) (Temperature ≥-20℃)

|

|||||

|

5

|

Low Temperature Viton (FKM-GFLT)

|

|||||

|

Process Connection

|

H

|

1/4” NPT F

|

||||

|

Maximum Pressure Limit

|

1

|

14 Mpa( 4Mpa for range 2)

|

||||

|

3

|

25 Mpa

|

|||||

|

5

|

32 Mpa

|

|||||

|

Cable Entry

|

1

|

M20*1.5

|

||||

|

Mounting Bracket

|

B00

|

None

|

||||

|

B01

|

Tube-type Curved Bracket (carbon steel)

|

|||||

|

B02

|

Wall mounting bracket (carbon steel)

|

|||||

|

B03

|

Tube-type Flat Bracket (carbon steel)

|

|||||

|

B04

|

Tube-type Curved Bracket (stainless steel)

|

|||||

|

B05

|

Wall mounting bracket (stainless steel)

|

|||||

|

B06

|

Tube-type Flat Bracket (stainless steel)

|

|||||

|

Optional

|

M3

|

LCD display

|

||||

|

d

|

Intrinsically safe type, Flameproof (Exd IIC T4~T6)

|

|||||

|

i

|

Intrinsically safe (Exia IIC T4~T6)

|

|||||

|

D1

|

Stainless steel drain valve or screw (2pcs)

|

|||||

|

C1

|

1/2” NPT female waist flange (2sets)

|

|||||

|

C12

|

1/2” NPT-M20*1.5-Φ14 pressure pipe (2sets)

|

|||||

|

C2

|

M20*1.5 male thread T joint (2sets)

|

|||||

|

C21

|

M20*1.5 T joint -Φ14 pressure pipe (2sets)

|

|||||

|

K1

|

Degreasing treatment

|

|||||

Contact us for more details about our boilers,solutions and services