Factory 220V RS485 Automatic Liquid Controller Quantitative Milk Oil Water Batch Box System LCD for Gas Air Fluid Valve Flow

| Medium | Liquids |

| Accuracy | 0.5% |

| Warranty | 1 Year |

| Power supply | 220VAC/ 24VDC |

Definition and Function

A Quantitative Control Cabinet is an integrated industrial automation system designed for precise measurement and control of materials in batch processes. It serves as the central command unit, automating the dispensing of liquids, powders, or granules according to pre-set formulas and quantities.

Key Features

High Precision & Stability: Utilizes advanced sensors (e.g., load cells, flow meters) and controllers to ensure extremely accurate measurements, minimizing material waste and ensuring product consistency.

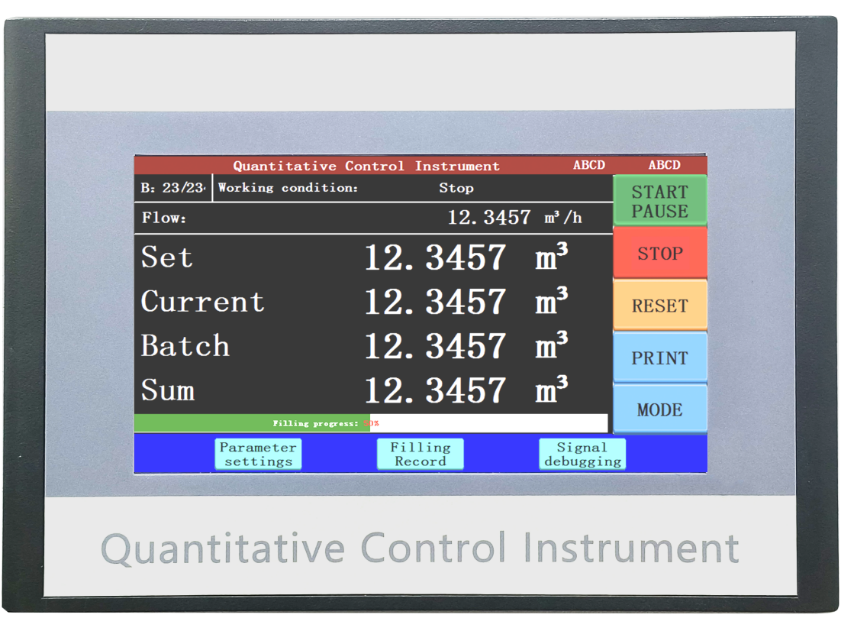

Integrated Automation: Combines a Programmable Logic Controller (PLC), human-machine interface (HMI), and robust electrical components. This enables fully automatic or semi-automatic control of valves, pumps, and conveyors.

User-Friendly Operation: Features a clear touchscreen HMI for easy formula input, process monitoring, parameter adjustment, and data review. Operation is simple and requires minimal manual intervention.

Flexibility & Versatility: Supports multiple formulas and batch sizes. The system can be customized with various weighing modules and actuator controls to suit diverse materials and process requirements.

Data Recording & Traceability: Often includes data logging functions to record batch history, production data, and operational logs, essential for quality control and production traceability.

Applications and Value

Widely used in industries like food & beverage, chemicals, pharmaceuticals, and construction (e.g., concrete batching), this cabinet enhances production efficiency, ensures strict formula adherence, improves safety by reducing human contact with materials, and significantly boosts overall process reliability and product quality.

未找到结果。