Understanding How Electromagnetic Flowmeters Work

Before diving into troubleshooting, it helps to quickly review how magmeters work.

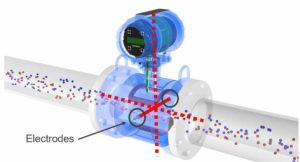

Electromagnetic flowmeters operate on Faraday¡¯s Law of Electromagnetic Induction: when a conductive fluid passes through a magnetic field, a voltage is induced that is directly proportional to the fluid¡¯s velocity.

The key components include:

Flow tube (non-conductive inner lining)

Electromagnetic coils

Electrodes (which detect the voltage)

Transmitter/display unit

No moving parts, low pressure drop, and the ability to handle sludges, slurries, or corrosive chemicals make them ideal for many industries.

However, their reliance on conductivity and stable flow conditions means installation and process factors greatly affect their performance.

Electromagnetic Flowmeter Common Signs of Inaccuracy

So how do you know your magmeter isn¡¯t reading properly?

Here are typical symptoms:

Fluctuating readings with no change in actual flow

Zero readings even when there is flow

Over-range or under-range outputs

Negative flow indications in a unidirectional system

Sudden spikes or drops in measured flow

Inconsistent outputs compared to other instruments (e.g., mass balance)

If you see any of these, it¡¯s time to take a systematic approach to diagnosing the issue.

Check for Zero Point Drift

One of the most overlooked causes of inaccurate readings is zero point drift ¡ª when the meter shows a non-zero reading even when there is no flow.

How to test:

Shut down the pump and fully isolate the flow.

Observe the flowmeter¡¯s reading ¡ª it should be exactly zero.

Causes of zero drift:

Residual voltage in the electronics

Magnetic field instability

Grounding issues

Buildup or coating on electrodes

Solution:

Use the transmitter¡¯s zero calibration feature.

Clean electrodes if buildup is visible.

Inspect the Electrical Grounding

Proper grounding and shielding are critical for electromagnetic flowmeters. Poor grounding can lead to:

Electrical noise

Spurious voltages

Oscillating or drifting readings

What to check:

Are grounding rings or electrodes installed?

Is the flowmeter connected to an isolated ground?

Is the shield of the signal cable grounded at one end only?

Improper grounding is a top reason for erratic behavior in magmeters.

Fix:

Follow the manufacturer¡¯s grounding diagram.

Ensure all process connections are electrically conductive where needed.

Avoid ground loops.

Evaluate the Flow Profile and Pipe Conditions

Flowmeters need a stable, laminar flow for accurate measurement. Poor flow profiles caused by bends, elbows, valves, or pumps nearby can induce swirling or turbulence.

Recommendations:

Install straight pipe before and after the meter (usually 5¨C10 diameters upstream, 3¨C5 downstream).

Use flow straighteners in space-constrained layouts.

Avoid installing directly downstream of control valves.

Even a perfectly functioning magmeter will produce false readings if flow is not well-developed.

Ensure Proper Electrode Contact

The electrodes in a magmeter need direct contact with the fluid. If there’s any coating, scaling, oil film, or biological growth, it will insulate the electrodes and lead to incorrect readings.

Fix:

Remove and inspect for fouling.

Clean gently using a non-abrasive pad or chemical cleaning solution recommended by the manufacturer.

Consider automatic cleaning features or switching to non-contact flowmeters if buildup is frequent.

Consider Process Fluid Conductivity

Electromagnetic flowmeters require the process fluid to be electrically conductive, typically above 5 ¦ÌS/cm.

If the fluid is:

Distilled water

Hydrocarbon-based

Ultra-pure solvents

…then a magmeter won¡¯t work reliably.

Fix:

Confirm the fluid conductivity with a lab test or sensor.

If too low, switch to another flowmeter type such as ultrasonic, vortex, or Coriolis.

Check for Air Bubbles or Entrained Gas

Air or gas pockets interrupt the conductive path between the electrodes, causing spikes, dropouts, or erratic behavior.

Causes:

Improper pipe slope

Air entrainment from upstream pumps

Gas pockets in multiphase flows

Fix:

Install air vents or degassers upstream.

Slope horizontal pipes upwards toward the meter.

Choose vertical installation (flow upward) when possible.

Minimize Electrical and Magnetic Interference

Electromagnetic meters can be sensitive to external fields from:

High-voltage cables

VFDs (Variable Frequency Drives)

Motors and transformers

Welding equipment

Fix:

Reroute signal cables away from high-energy sources.

Use twisted pair and shielded signal wires.

Install ferrite beads or filters if noise is significant.

Verify Calibration and Configuration Settings

Software errors and misconfigurations can also lead to inaccurate readings. Always verify:

Flow units (e.g., m3/h vs. gpm)

Empty pipe detection settings

Damping filters or signal averaging

Sensor scaling and K-factor entries

If the transmitter was replaced, factory reset, or updated, settings may have reverted or changed.

When to Replace or Service the Flowmeter

If you¡¯ve gone through all the above and still face inaccuracies, the issue may be with the hardware itself.

Signs you may need repair or replacement:

Internal diagnostics report faults

Electrodes corroded beyond cleaning

Sensor liner damaged or eroded

Transmitter malfunctioning

Most manufacturers offer return-to-factory testing or on-site servicing. Also, consider the age of the meter ¡ª most last 10¨C15 years under normal conditions.

Conclusion: Diagnose Early, Fix Smart

Here¡¯s a quick troubleshooting checklist:

? Check for zero flow drift

? Inspect grounding and shielding

? Verify upstream/downstream pipe runs

? Clean and inspect electrodes

? Confirm fluid conductivity

? Eliminate bubbles and turbulence

? Review transmitter settings

? Test for interference

? Consider recalibration or replacement

By resolving these factors, you¡¯ll ensure your flowmeter delivers the reliable, accurate performance your operation depends on. And remember ¡ª preventive maintenance is always cheaper than unexpected downtime.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument