Introduction: The Unseen Workhorse of Flow Measurement

Inaccurate flow readings in challenging applications like raw sewage or corrosive chemical streams can cripple process efficiency and lead to costly errors. For engineers and procurement specialists seeking unwavering reliability in liquid flow measurement, the Electromagnetic Flow Meter stands as an indispensable solution. Unlike traditional meters susceptible to clogging or pressure loss, this technology leverages fundamental physics to deliver precise, repeatable data for a vast array of conductive fluids.

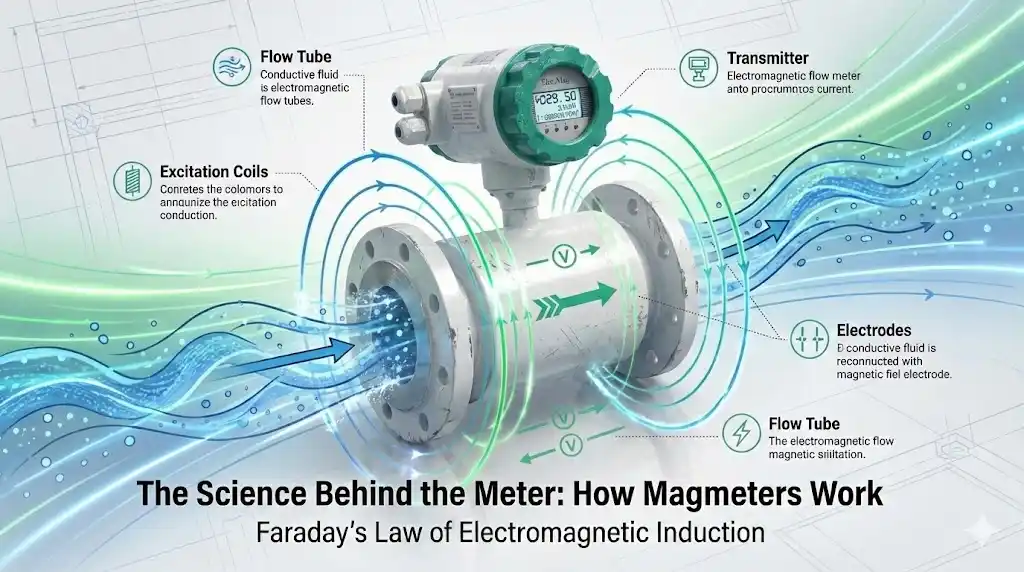

The Science Behind the Meter: How Magmeters Work

At its core, the electromagnetic flow meter operates on a simple yet powerful principle: Faraday’s Law of Electromagnetic Induction. When a conductive fluid moves through a magnetic field, it generates a voltage proportional to its velocity. This induced voltage is then measured and converted into a flow rate reading.

- Faraday’s Law Explained: Imagine a wire cutting through a magnetic field. This action creates an electrical current. In a magmeter, the conductive fluid acts as the “wire,” and the magnetic field is generated by internal coils. The faster the fluid moves, the stronger the induced voltage.

The meter consists of several key components working in concert:

- Flow Tube: Houses the conductive fluid, often lined with materials like PTFE or PFA.

- Excitation Coils: Generate a stable magnetic field across the flow tube.

- Electrodes: Strategically placed to measure the voltage induced by the fluid’s movement.

- Transmitter: Processes the raw voltage signal and converts it into a usable flow rate output (e.g., 4-20mA, pulse).

Understanding the components is just the first step. To ensure these components survive your specific process environment, you must choose the right materials. We cover this in detail in Part 2: Magmeter Selection & Installation Guide.

Benefits of the Design

This design offers significant advantages:

- Zero Pressure Drop: No internal obstructions affect system pressure.

- Linear Output: The voltage signal directly correlates with flow velocity.

- Wide Rangeability: Accurately measures both high and low flow rates within the same meter.

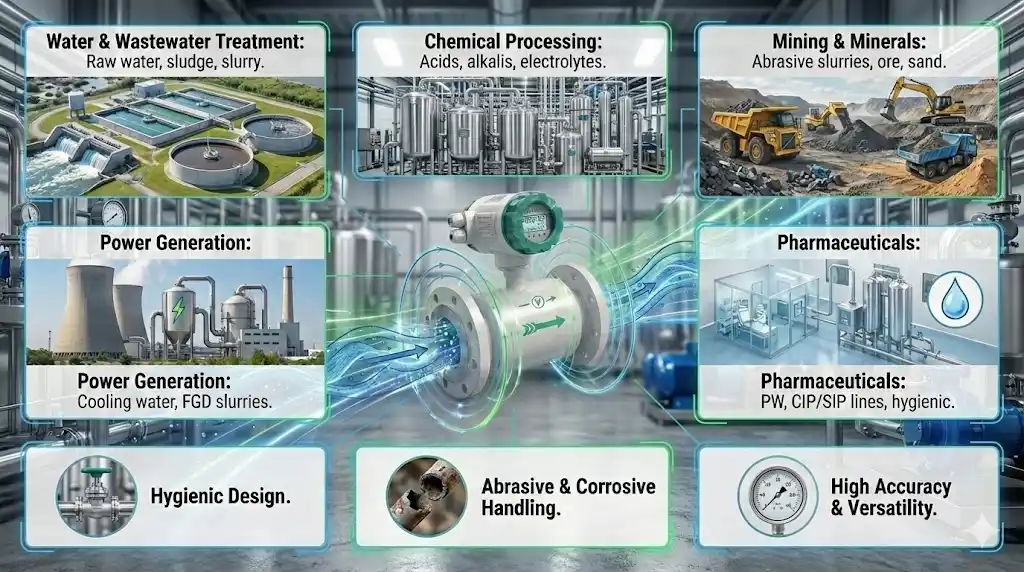

Industry-Specific Applications: Where Magmeters Shine

Electromagnetic flow meters are highly versatile and excel in applications where other flow meter technologies struggle.

- Water and Wastewater Treatment: From raw water intake to sludge and slurry transfer.

- Chemical Processing: Ideal for acids, alkalis, and electrolytes where material compatibility is key.

- Mining and Minerals: Handling abrasive slurries of ore, sand, and gravel.

- Power Generation: Cooling water and Flue Gas Desulfurization (FGD) slurries.

- Pharmaceuticals: Measuring Purified Water (PW) and CIP/SIP lines for hygienic processes.

Conclusion

By properly applying Faraday’s Law of Induction, users can leverage magmeters’ strengths. Their inherent robustness makes them a cornerstone technology. However, even the best technology fails if installed incorrectly.

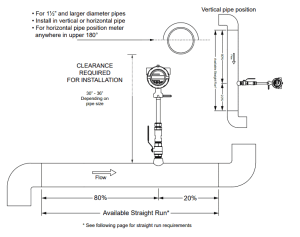

NEXT STEP: Ready to implement this technology? Proceed to our next article to learn how to spec and install your meter correctly: Read Part 2: Selection & Installation Guide.