This comprehensive guide explores what high viscosity oil flow meters are, how they work, why they matter, and which technologies are best suited for various heavy-duty applications. Whether you’re a plant engineer, procurement specialist, or facility manager, this article will help you make informed decisions for improving process efficiency and operational accuracy.

What Is High Viscosity Oil?

Viscosity is the measure of a fluid’s resistance to flow. The thicker the fluid, the higher its viscosity. High viscosity oils include:

-

Crude oil

-

Heavy fuel oil

-

Lubricants

-

Greases

-

Hydraulic oils

These oils don’t flow easily, especially at lower temperatures. That’s why they require special flow measurement tools that can handle their sluggish nature without compromising accuracy.

Why Measuring Viscous Oil Accurately Matters

In many heavy industries, oil isn’t just a fuel—it’s a critical process input. Inaccurate flow measurement can lead to:

-

Process inefficiencies

-

Material waste

-

Increased costs

-

Inconsistent product quality

Accurate flow monitoring of high-viscosity oils ensures precise dosing, optimized blending, and improved energy use, making your operation more reliable and cost-effective.

Challenges of Measuring High Viscosity Fluids

Standard flow meters are often designed for water-like fluids. However, high-viscosity oils behave differently, introducing several measurement challenges:

-

High resistance to flow causes pressure drops

-

Temperature sensitivity impacts viscosity and flow rate

-

Tendency to clog or coat sensors

-

Low flow conditions are harder to detect

-

Non-Newtonian behavior in some oils affects readings

To address these challenges, industries turn to specialized high viscosity flow meters built to deliver accurate, repeatable measurements even under harsh conditions.

What Is a High Viscosity Oil Flow Meter?

A high viscosity oil flow meter is a device specifically designed to accurately measure the flow rate of thick fluids. These meters are engineered with low-pressure drop designs, larger internal clearances, and robust materials to handle sticky, slow-moving oils.

These meters often include positive displacement, Coriolis, or gear-based mechanisms, as these technologies perform best with high-viscosity fluids.

Types of Flow Meters for High Viscosity Oil

Let’s break down the top technologies used for measuring viscous oils in industrial applications:

| Flow Meter Type | Best For | Accuracy | Viscosity Range |

|---|---|---|---|

| Positive Displacement (PD) | Greases, Lube Oils, Fuel Oils | ±0.1-0.5% | Wide (very high) |

| Coriolis | Crude Oil, Heavy Fuel | ±0.1-0.2% | Broad (low to very high) |

| Gear Flow Meters | Lubricants, Additives | ±0.3-0.5% | Medium to high |

| Ultrasonic / Thermal Mass | Less suitable for viscous fluids | ±1-2% | Low to medium |

Positive Displacement Flow Meters

Positive Displacement (PD) flow meters are often the go-to solution for high-viscosity fluids. These meters work by capturing a fixed amount of fluid in a chamber and then mechanically moving it through the meter.

Advantages:

-

Extremely accurate and repeatable

-

Handle low flow rates well

-

Performance is not significantly affected by viscosity changes

-

No need for a power supply (mechanical types)

Common PD Technologies:

-

Rotary vane

-

Oval gear

-

Helical gear

-

Nutating disc

These meters are widely used in lubrication systems, oil blending, and fuel dispensing.

Coriolis Flow Meters

Coriolis meters measure mass flow and are highly accurate regardless of the fluid’s properties. They’re an excellent choice for viscous and variable fluids, even those with entrained gas or particulates.

Why Coriolis Is a Top Choice:

-

Provides direct mass flow, unaffected by viscosity

-

Measures density and temperature simultaneously

-

Ideal for custody transfer and high-value fluids

The only downside? They’re expensive, and pressure drop can be higher than PD meters for very thick oils. But in high-precision or high-stakes environments, Coriolis meters often pay for themselves.

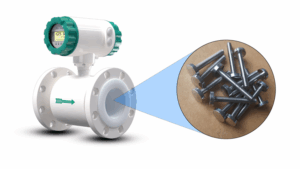

Gear Flow Meters

Gear meters are a subset of PD meters and work by measuring the rotation of gears as fluid passes through them. These are common in lubricant production, dosing systems, and hydraulic applications.

Key Benefits:

-

High accuracy and repeatability

-

Compact design

-

Suitable for high pressure systems

-

Handles moderately to highly viscous fluids

However, they may not be ideal for extremely dirty or abrasive oils, as the gears are sensitive to particulates.

Thermal Mass and Ultrasonic Flow Meters: Are They Viable?

While thermal mass and ultrasonic flow meters are widely used in industrial settings, they are generally not ideal for high viscosity applications.

Thermal Mass:

-

Measures gas flow well but struggles with thick liquids

-

Often inaccurate with sticky or coating-prone fluids

Ultrasonic:

-

Works best with clean, low-viscosity liquids

-

Viscous fluids absorb sound waves, reducing signal strength and accuracy

In short, use these technologies cautiously when dealing with heavy oils. They’re better suited for low-viscosity fluids or gas applications.

Key Considerations When Choosing a Flow Meter

Selecting the right flow meter isn’t just about choosing the “best” technology—it’s about finding the right fit for your process. Here’s what to evaluate:

-

Viscosity range of the oil

-

Flow rate (low or high)

-

Operating temperature and pressure

-

Cleanliness of the oil (presence of particles)

-

Required accuracy

-

Installation constraints (size, orientation, footprint)

-

Budget

Don’t underestimate the impact of viscosity changes with temperature—you may need a meter that compensates automatically or works across a broad range.

Industries That Rely on High Viscosity Oil Flow Meters

Many heavy-duty industries depend on high viscosity oil flow meters for their day-to-day operations, including:

-

Oil & Gas: For measuring crude, bitumen, and bunker fuel

-

Marine & Shipping: Fuel monitoring and engine lubrication

-

Power Generation: For turbine oils and gear lubricants

-

Food & Beverage: Thick sauces, syrups, and vegetable oils

-

Automotive: Engine oil filling and blending

-

Chemical Processing: Resin, additive, and lube oil measurement

-

Manufacturing: Hydraulic fluids and metalworking oils

In all these applications, accuracy, durability, and compatibility are non-negotiable.

Conclusion

When it comes to measuring the flow of high viscosity oils, not just any flow meter will do. Standard meters fail under the stress of thick fluids, but specialized options like positive displacement, Coriolis, and gear flow meters rise to the challenge.

By investing in the right technology, heavy-duty industries can ensure greater process control, reduced waste, and optimized efficiency. Whether you’re handling sticky lubricants or thick crude, there’s a flow meter built to handle it—and your bottom line will thank you for

choosing wisely.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument