When it comes to measuring fluid flow in industrial processes, there’s no shortage of options. From turbine meters to ultrasonic sensors, each method has its pros and cons. However, magnetic flowmeters — often referred to as magmeters — have become increasingly popular due to their precision and durability. But the big question remains: Are magnetic flowmeters worth it? We asked the experts, analyzed the data, and compiled this in-depth guide to help you decide.

What Is a Magnetic Flowmeter?

A magnetic flowmeter is a type of volumetric flowmeter that measures the flow rate of liquid using Faraday’s Law of Electromagnetic Induction. In simple terms, when a conductive fluid flows through a magnetic field, it generates a voltage. This voltage is proportional to the flow rate, and the flowmeter uses it to determine how much liquid is passing through.

These devices are commonly used in water and wastewater treatment, chemical manufacturing, food and beverage production, and pharmaceutical processing — industries where reliability and accuracy are paramount.

How Do Magnetic Flowmeters Work?

The operating principle behind magnetic flowmeters is both elegant and efficient:

-

Electromagnetic coils generate a magnetic field inside the pipe.

-

As a conductive liquid flows through the field, it produces a voltage.

-

Electrodes on the pipe walls detect this voltage.

-

The signal is processed and converted into flow rate data.

Since the measurement depends on the conductivity of the fluid, magmeters won’t work for non-conductive fluids like oils or pure deionized water.

Advantages of Magnetic Flowmeters

Experts praise magnetic flowmeters for a number of compelling reasons:

1. No Moving Parts

Because magnetic flowmeters have no mechanical components, they are far less prone to wear and tear, making them ideal for long-term, low-maintenance use.

2. Highly Accurate

Many magmeters offer ±0.2% accuracy, which is suitable for even the most demanding applications.

3. Minimal Pressure Drop

Since there’s nothing obstructing the fluid flow inside the pipe, pressure loss is virtually nonexistent.

4. Versatility Across Industries

From measuring sludge in wastewater treatment plants to sugary syrups in beverage factories, magmeters handle a wide range of viscous and abrasive fluids.

5. Bidirectional Flow Measurement

Magnetic flowmeters can measure forward and reverse flow, offering flexibility that’s hard to find in other flowmeter technologies.

Disadvantages of Magnetic Flowmeters

Even the best tools come with limitations, and magmeters are no exception. Here’s what experts caution:

1. Not Suitable for Non-Conductive Fluids

Magnetic flowmeters require conductivity (typically above 5 μS/cm) to function. This rules out hydrocarbons, oils, and gases.

2. Higher Initial Cost

Compared to some traditional flowmeters, magmeters can be expensive upfront, especially for large pipe sizes.

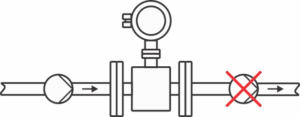

3. Installation Complexity

Proper grounding and sensor alignment are critical for accurate measurement, which can complicate installation in older systems.

Magnetic Flowmeters vs. Other Flowmeter Types

To better understand the value of magnetic flowmeters, let’s compare them to other common types:

Turbine Flowmeters

-

Pros: Inexpensive, suitable for clean liquids.

-

Cons: Have moving parts, require maintenance, affected by viscosity.

Ultrasonic Flowmeters

-

Pros: Non-invasive, works with a variety of fluids.

-

Cons: Less accurate, susceptible to air bubbles and pipe scaling.

Coriolis Flowmeters

-

Pros: High accuracy, measures mass flow directly.

-

Cons: Very expensive, large and heavy.

In many cases, magmeters offer the best balance between performance, reliability, and cost, especially in medium to large-scale operations.

When Are Magnetic Flowmeters Worth the Investment?

According to industry specialists, magnetic flowmeters are absolutely worth the investment if you meet the following conditions:

-

You are dealing with conductive fluids.

-

You need high accuracy and low maintenance.

-

Your process demands consistent, long-term performance.

-

You want to avoid pressure drops or mechanical failures.

For these reasons, magnetic flowmeters are often the go-to choice in municipal water systems, chemical processing, and pulp and paper mills.

Cost Analysis: Initial vs. Lifetime Value

While magmeters might cost more upfront, they often pay for themselves over time through:

-

Reduced maintenance costs

-

Minimized downtime

-

Improved process control

-

Extended lifespan (10-20 years)

Many experts recommend evaluating the total cost of ownership (TCO) rather than just the initial price tag. When you consider efficiency gains, labor savings, and operational reliability, magmeters often emerge as the smarter long-term investment.

Key Features to Look For in a Magnetic Flowmeter

If you’re considering a magmeter, don’t just buy the first one you see. Here are some features worth prioritizing:

1. Liner Material Compatibility

Choose liners like PTFE or rubber based on your fluid’s chemical composition and temperature.

2. Electrode Design

Opt for non-intrusive or flush-mounted electrodes in dirty or slurry applications.

3. Communication Protocols

Ensure compatibility with your existing systems — options include Modbus, HART, Profibus, and Ethernet/IP.

4. Built-in Diagnostics

Advanced models offer self-diagnostics and alerts, which can dramatically reduce troubleshooting time.

Real-World Case Studies

Water Treatment Plant in California

Switched from mechanical meters to magmeters and reported:

-

30% reduction in maintenance costs

-

15% improvement in measurement accuracy

-

Zero unplanned downtime over 3 years

Food Processing Facility in Germany

Needed hygienic, CIP-compatible meters for syrup and dairy:

-

Installed stainless steel magmeters with PTFE liners

-

Achieved consistent flow control and regulatory compliance

These examples highlight the practical value of magnetic flowmeters in demanding environments.

Expert Opinions

We asked engineers and process control specialists their thoughts on magnetic flowmeters. Here’s a summary of their responses:

“They’re not the cheapest, but they’re definitely the most reliable for conductive fluids.” – Process Engineer, Chemical Industry

“We’ve standardized on magmeters across our plants. Maintenance is practically nonexistent.” – Instrumentation Manager, Water Utility

“For anyone dealing with slurries or harsh chemicals, it’s a no-brainer.” – Senior Automation Engineer, Pulp & Paper Mill

Their consensus? If the fluid is conductive and your operation depends on accurate, uninterrupted flow data, magmeters are well worth the investment.

Future Trends in Magnetic Flowmeter Technology

As industries shift toward Industry 4.0, magnetic flowmeters are evolving with features like:

-

Wireless connectivity

-

Edge computing capabilities

-

AI-based diagnostics

-

Cloud integration

These advances are making magmeters not just a measurement tool, but a key component in smart, data-driven operations.

Conclusion: Are Magnetic Flowmeters Worth It?

Absolutely — for the right applications. If your process involves conductive liquids, demands high accuracy, and would benefit from low maintenance and long service life, then magnetic flowmeters are an excellent investment.

While the upfront cost may be higher than other types, the long-term benefits, from operational efficiency to maintenance savings, make magnetic flowmeters a top choice for many industries.

So next time you’re weighing flowmeter options, remember: It’s not just about price — it’s about performance, reliability, and peace of mind.