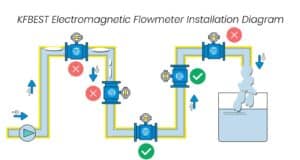

As an electromagnetic flowmeter is installed, it is a process that needs to be taken seriously to ensure precision and long-time stable performance of electromagnetic flow measurement.

Cautions of the installation of electromagnetic flowmeter

- The electromagnetic flowmeter has to be assured of functionality at full pipe conditions. Excessive or no water in the pipe will cause improper functioning of the flowmeter.

- The electromagnetic meter of water flow cannot be fixed in the highest point of the pipe. As indicated in the Figure 1: Installed flowmeter electromagnetic

- When installing the product, the flow of the liquid is to be generally in the same direction of the arrow.

- The installation of the electromagnetic flowmeter is horizontally and vertically. As a rule, when the measuring electrode is installed horizontally, it is preferable to ensure that its axis is somewhat horizontal.

- There must be no big source of vibration around the installation area Reinforcement should therefore be done on a both sides of the instrument to hold on the nearby pipelines so that the flowmeter does not get the strain produced by the vibration of pipelines, impacts and contractions.

- The electromagnetic flowmeter cannot be located close to sources likely to interfere with it or inductively, strong interference, e.g., motors, transformers, and pumps.

What are the straight pipe requirements for a magnetic flow meter?

The straight pipe specifications are preference to the places of business installation. It is suggested that electromagnetic flowmeter must be mounted in the pipeline as follows:

| Installation Location | Installation Requirements |

| installed between two valves |  |

| installed at the back end of the T-tube |  |

| installed at the back end of the 90°elbow pipe |  |

| at the back end of the expanded diameter pipe |  |

| installed at the back end of the valve (the valve is not fully open) |  |

Electromagnetic internal threaded like pre-help thy were threaded flowmeters?

A: No. The default is external threads Internal threads can make the lining fall off. Adapters are in a position to meet this requirement

Can Electromagnetic flow meters of the inline type be used in an area of negative pressure?

There is no general recommendation of inline type electromagnetic flowmeters in negative pressure environment. Too much negative pressure can dislodge the electrode off the lining and touch the housing resulting in a circuit conduction.

How do you guard against lightning strikes to electromagnetic flowmeters?

- The most basic and important lightning protection measure is grounding. Both ends of the electromagnetic flowmeter sensor have to be properly grounded. This will avoid voltage transients and surges due to lighting damaging the instruments.

- Shielding: The signal signal of the electromagnetic flowmeter should be lined with galvanized pipe. It can have no more than 50 meters in length. This may minimize the noise and destruction that accompanies lightning via the signal line.

- Equipotential connection: Grounded means that all potentially high voltages (transmitters and sensors, etc.) are connected to a low-impedance ground wire. These sections can be at the equal levels of the potential during the occurrence of lightning, which prevents the creation of the high local voltage.

- Lightning arrester: Electromagnetic flowmeter mounts lightning arresters on the power and signal cables. The maximum length of the lightning arrester grounding wire has to not be longer than 1 meter, and the cross-section should be more than 6 square millimeters of the multi-conductor copper core covered wire.

The above-mentioned comprehensive measures are effective in enhancing the safety and stability of the electromagnetic flowmeter in the incidence of adverse weather.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument