Measuring the flow of seawater is essential in many industries, including desalination plants, offshore oil and gas, marine engineering, coastal power stations, and environmental monitoring. Unlike freshwater, seawater poses unique challenges due to its high salinity, conductivity, and corrosive nature. Therefore, selecting the right flowmeter is not just a technical choice but a crucial decision for ensuring accuracy, durability, and long-term cost-effectiveness.

In this article, we will explore the different types of flowmeters, evaluate their performance in seawater applications, and identify which option is the most suitable. By the end, you will have a clear understanding of how to select the best flowmeter for seawater measurement.

1. Understanding the Challenges of Measuring Seawater

Before choosing a flowmeter, it¡¯s important to recognize what makes seawater measurement different from other fluids:

High salinity and conductivity: Seawater typically has a salinity of around 35,000 ppm, making it highly conductive. This property is beneficial for some flowmeter types but problematic for others.

Corrosive environment: Chlorides in seawater can aggressively corrode common metals like carbon steel and even stainless steel if not properly protected.

Presence of solids and biological matter: Sand, algae, and marine organisms can interfere with measurement, clogging moving parts.

Wide range of flow conditions: Applications can involve low or very high flow rates, requiring versatile measurement technology.

Given these conditions, the ideal seawater flowmeter must be corrosion-resistant, accurate, and reliable with minimal maintenance needs.

2. Types of Flowmeters Commonly Considered for Seawater

There are several flowmeter technologies available, but not all are equally effective for seawater. Let¡¯s review the main types:

Electromagnetic Flowmeter (Magmeter)

Ultrasonic Flowmeter

Coriolis Mass Flowmeter

Turbine Flowmeter

Differential Pressure (Orifice Plate) Flowmeter

Each type has its strengths and weaknesses in seawater applications.

3. Electromagnetic Flowmeters for Seawater

Electromagnetic flowmeters (magmeters) are one of the most widely recommended solutions for seawater measurement.

How it works: Magmeters measure flow using Faraday¡¯s law of electromagnetic induction, which requires the fluid to be conductive.

Why suitable for seawater: Since seawater is highly conductive, magmeters perform exceptionally well.

Advantages:

High accuracy (¡À0.2% to ¡À0.5%).

No moving parts, reducing wear and maintenance.

Suitable for large pipe diameters.

Wide turndown ratio (can measure low and high flows).

Considerations:

The lining and electrodes must resist corrosion. Common choices include PTFE lining with Hastelloy, titanium, or tantalum electrodes.

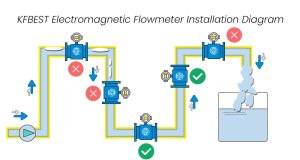

Requires proper grounding and installation.

?? Verdict: Best overall choice for seawater, especially in desalination, wastewater outfalls, and industrial cooling systems.

4. Ultrasonic Flowmeters for Seawater

Ultrasonic flowmeters use sound waves to measure flow velocity. They come in clamp-on (non-intrusive) and inline types.

Advantages:

Clamp-on models require no pipe cutting¡ªperfect for retrofit applications.

No direct contact with seawater, avoiding corrosion issues.

Suitable for very large pipes or temporary measurements.

Limitations:

Accuracy (¡À1% to ¡À3%) is generally lower than magmeters.

Performance can be affected by bubbles, suspended solids, or fouling on pipe walls.

Requires a good straight pipe length for accurate readings.

?? Verdict: Excellent for applications where non-intrusive installation is preferred or when measuring flow in very large pipelines.

5. Coriolis Mass Flowmeters for Seawater

Coriolis flowmeters measure mass flow directly by detecting vibrations in the fluid stream.

Advantages:

High accuracy (¡À0.1%).

Measures both mass flow and density, which can be useful for seawater applications.

Works independently of fluid conductivity.

Limitations:

Expensive compared to other types.

Size and cost make them less practical for very large seawater pipelines.

Higher pressure drop compared to magmeters.

?? Verdict: Best for high-value processes requiring both mass flow and density data, such as research, dosing, or specialized marine engineering projects.

6. Turbine Flowmeters for Seawater

Turbine flowmeters use a rotor that spins in proportion to the fluid velocity.

Advantages:

Good accuracy in clean fluids.

Relatively low cost compared to Coriolis or magmeters.

Limitations:

Moving parts are prone to wear and corrosion in seawater.

Requires special materials like titanium or duplex stainless steel to resist saltwater damage.

Not suitable for dirty or particle-laden seawater.

?? Verdict: Only suitable for specific clean seawater applications with corrosion-resistant construction. Maintenance is higher compared to other options.

7. Differential Pressure (Orifice Plate) Flowmeters

This traditional method measures flow by detecting pressure drop across an orifice plate.

Advantages:

Simple design and low cost.

Widely available.

Limitations:

Lower accuracy than modern flowmeters.

Pressure loss in the system.

Prone to fouling from biological matter and suspended solids in seawater.

?? Verdict: Rarely the first choice for seawater, better suited for basic monitoring where low cost outweighs precision.

8. Material Selection for Seawater Flowmeters

The flowmeter¡¯s material compatibility is as important as the technology itself. Seawater corrodes many metals, so material choice is critical.

Recommended materials:

Electrodes/parts: Titanium, Hastelloy, or Tantalum.

Linings: PTFE, rubber, or ceramic for magmeters.

Housing: Duplex or super duplex stainless steel for durability.

Using inappropriate materials can drastically shorten the life of the instrument.

9. Key Factors to Consider When Choosing a Flowmeter for Seawater

When deciding which flowmeter to use, evaluate these factors:

Accuracy requirements ¨C Is precision critical or is an approximate reading sufficient?

Pipe size ¨C Some technologies are more cost-effective for large diameters.

Installation type ¨C Do you need an inline, insertion, or clamp-on design?

Maintenance needs ¨C Are you able to perform regular cleaning and calibration?

Budget ¨C Coriolis flowmeters are expensive, while orifice plates are cheap but less accurate.

Application environment ¨C Offshore platforms, desalination plants, and cooling systems each have unique demands.

10. Comparison Table: Flowmeters for Seawater

| Flowmeter Type | Accuracy | Corrosion Resistance | Maintenance | Best Applications |

|---|---|---|---|---|

| Electromagnetic | ¡À0.2¨C0.5% | Excellent (with correct lining/electrodes) | Low | Desalination, cooling water, wastewater discharge |

| Ultrasonic | ¡À1¨C3% | Excellent (clamp-on) | Very Low | Large pipelines, retrofit, non-intrusive |

| Coriolis | ¡À0.1% | Good (with proper materials) | Medium | High-precision dosing, density measurement |

| Turbine | ¡À0.5¨C1% | Fair (with special alloys) | High | Clean seawater, smaller systems |

| Orifice Plate | ¡À1¨C3% | Moderate | Medium | Low-cost, non-critical applications |

11. Best Flowmeter for Seawater Applications

After evaluating all options, the electromagnetic flowmeter stands out as the most suitable for seawater measurement. Its combination of high accuracy, corrosion resistance, and low maintenance makes it the go-to solution in most industrial and environmental settings.

For situations where installation must be non-intrusive, the ultrasonic clamp-on flowmeter is the next best option. If mass flow and density are critical, a Coriolis flowmeter may be justified despite the cost.

Conclusion

Choosing the right flowmeter for seawater is not a one-size-fits-all decision. Factors such as accuracy, corrosion resistance, installation type, and budget all play key roles.

Among the available options, the electromagnetic flowmeter remains the best overall choice due to its reliability, durability, and suitability for conductive fluids like seawater. For specific needs, ultrasonic, Coriolis, or turbine flowmeters may also be appropriate.

By carefully considering your application requirements and selecting the right materials, you can ensure accurate, long-lasting seawater flow measurement¡ªreducing downtime, maintenance costs, and operational risks.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –KFBEST