In the complex world of industrial automation, whether you are dealing with chemical processing or municipal water treatment, two unsung heroes work tirelessly behind the scenes: flow meters and valves.

These two components are often treated as separate entities. However, the truth is that they are deeply interconnected. In fact, understanding the dynamic relationship between flow meters and valves is the secret sauce for smarter system design.

If you are an engineer or a technician, you know the struggle. Designing a system that is both efficient and precise can feel like a balancing act. But don’t worry. In this guide, we’ll explore how these devices influence each other and how you can master their coordination.

What Are Flow Meters? (The “Eyes”)

Think of flow meters as the “eyes” of your system. They are devices designed to measure the flow rate of a fluid, whether it is liquid, gas, or steam.

There are several common types of flow meters, including:

- Electromagnetic (Magmeters)

- Ultrasonic

- Turbine

- Coriolis

- Thermal mass

- Differential pressure

Each type has its own superpower, depending on the application and the fluid involved. Ultimately, they provide the critical data needed for monitoring. In industries where precision equals safety, this data is non-negotiable.

What Are Valves? (The “Hands”)

If flow meters are the eyes, valves are the “hands.” They are mechanical devices that control the flow by opening, closing, or partially obstructing the path.

Common players in this field include:

- Ball valves

- Gate valves

- Globe valves

- Butterfly valves

- Control valves (actuated or manual)

Unlike meters, which simply watch the flow, valves actively regulate it. They are essential for maintaining pressure and directing movement.

The Synergy: Why Measuring and Controlling Flow Matters

To manage any fluid system effectively, you need a partnership. You need both data and mechanical control. This is where the synergy between flow meters and valves becomes vital.

Think of it this way:

A flow meter says, “We are running at 50 liters per minute.” A valve replies, “Understood. I’ll open up to increase that to 75 L/min.”

Together, they create a feedback loop. This ensures that your system operates within its “Goldilocks zone”—not too fast, not too slow, but just right.

How Valves Can Impact Flow Meter Accuracy

Here is a hard truth: a poorly placed valve can ruin your flow meter’s day.

One of the most critical aspects of their relationship is how valves directly affect measurement accuracy. Let’s break down the risks.

1. Turbulence Generation

Imagine trying to read a book while someone is shaking your chair. That is what happens when a valve is placed immediately upstream of a meter. It creates turbulence.

This swirling, uneven flow makes readings unstable, particularly for turbine and ultrasonic meters.

2. Pressure Drop Effects

Valves create pressure drops, especially when they are partially closed. Consequently, sensitive instruments like Coriolis meters might react to this pressure loss by registering false flow rates.

3. Flow Obstruction

Sometimes, a valve might obstruct flow in a way that mimics a system fault. This can lead operators down a rabbit hole, believing the meter is broken when it is actually just a valve issue.

Key takeaway: If you don’t design your layout carefully, your valve might be lying to your meter.

How Flow Meters Influence Valve Control Logic

Valves are no longer just dumb mechanical switches. In modern systems, they act as the muscles in a PID (Proportional, Integral, Derivative) control loop. But muscles need a brain to tell them what to do.

Real-Time Feedback Flow meters provide the real-time velocity or volume data. This data is fed into a controller (like a PLC). Subsequently, the controller commands the valve to adjust.

Fine-Tuned Adjustments Without this loop, processes like batch dosing or chemical injection would be a guessing game. Without a flow meter, a valve is operating blindly. As a result, overshooting or undershooting your target becomes inevitable.

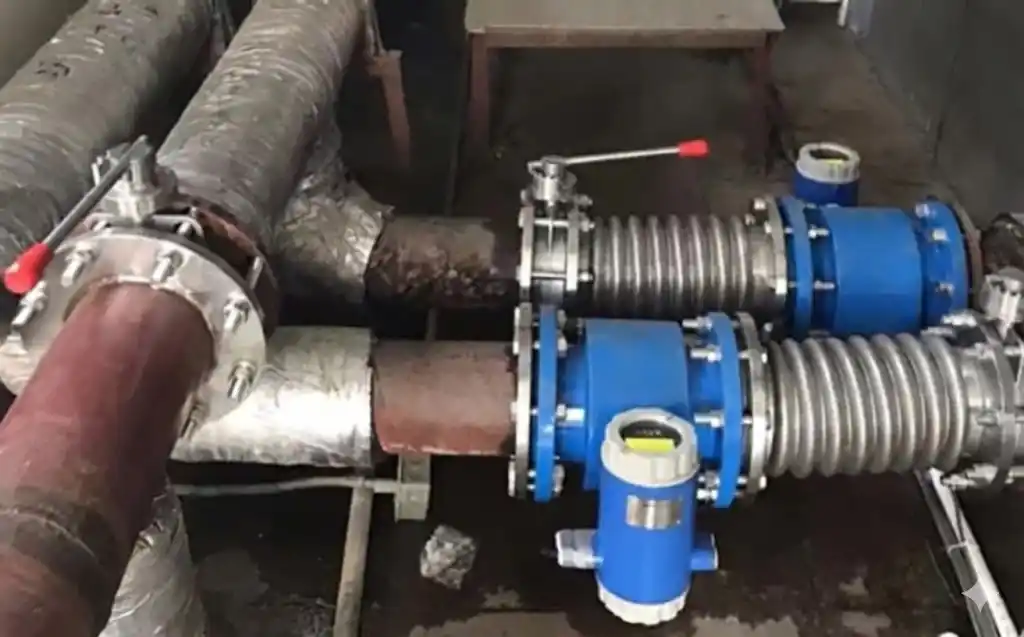

Ideal Installation Practices for Flow Meters and Valves

To ensure your system runs like a well-oiled machine, placement is everything.

General Guidelines:

- Go Upstream: Whenever possible, install flow meters upstream of control valves.

- Keep it Straight: Maintain straight pipe runs before and after the meter (usually 5–10 pipe diameters).

- Avoid Noise: Don’t place meters near pumps or elbows that create disturbances.

- Vent it Out: Use air vents if bubbles are likely to form.

The Million-Dollar Question: Valve Before or After?

Should the valve go before or after the meter? The answer is almost always after.

Valve Upstream (Before): This is risky. It causes turbulence and pressure fluctuations. Avoid this unless the valve is always fully open.

Valve Downstream (After): This is the recommended spot for Integrated Type Electromagnetic Flowmeter, Ultrasonic, and Turbine meters. It keeps the flow stable and “fully developed” as it enters the meter, ensuring you get the accuracy you paid for.

Common Issues Caused by Poor Coordination

When the relationship between flow meters and valves is ignored, things go wrong fast. You might encounter:

- Oscillating flow rates.

- Unstable or jumpy readings.

- Sensor drift.

- Pump cavitation due to pressure loss.

Most of these headaches can be traced back to one thing: incorrect placement or a lack of calibration.

Best Practices for Seamless Integration

We know that troubleshooting these issues is frustrating. To avoid them, follow these proven best practices:

- Choose Compatible Technologies: Match your meter to a valve that doesn’t create unnecessary chaos. For precision, a globe valve often beats a butterfly valve.

- Use Flow Conditioners: Tight on space? Install flow straighteners upstream of the meter to calm the turbulence.

- Calibrate Regularly: Ensure both devices are singing from the same song sheet.

- Go Smart: Use digital protocols like HART or Profibus to enable two-way communication.

Conclusion: A Symbiotic Relationship

The relationship between flow meters and valves is not just about convenience; it is about necessity.

In today’s automation-driven world, these two components form a dynamic partnership. When integrated correctly, they enhance each other. However, when separated, they fail.

Think of it like driving a car. A flow meter without a valve is like a speedometer without a throttle—you know how fast you are going, but you can’t change it. Conversely, a valve without a flow meter is like a gas pedal with no windshield—you have power, but you are driving blind.

By understanding this connection, you can build smarter, more responsive systems. Whether you are in oil and gas or manufacturing, investing in the coordination of flow meters and valves pays dividends in performance and peace of mind.