When it comes to measuring flow accurately in industrial applications, choosing the right flow meter is absolutely critical. Two of the most popular and reliable technologies on the market are vortex flow meters and magnetic (or electromagnetic) flow meters. While they both serve the purpose of flow measurement, their working principles, installation requirements, accuracy, and ideal applications vary significantly.

In this comprehensive guide, we¡¯ll break down everything you need to know about vortex flow meters vs magnetic flow meters, helping you make an informed choice based on your specific process conditions.

What Is a Vortex Flow Meter?

A vortex flow meter measures the flow rate of liquids, gases, and steam by detecting vortices (swirling motions) generated as the fluid flows past a bluff body (a fixed obstruction). This is based on the von K¨¢rm¨¢n effect, where vortices are shed alternately from both sides of the body.

Key Features of Vortex Flow Meters

No moving parts, resulting in minimal wear and tear.

Suitable for liquids, gases, and steam.

Provides volumetric flow rate.

Works best with clean, low-viscosity fluids.

Can handle high temperatures and pressures.

What Is a Magnetic Flow Meter?

A magnetic flow meter, also known as a magmeter, works on Faraday¡¯s Law of Electromagnetic Induction. As a conductive fluid flows through a magnetic field inside the meter, it induces a voltage that is directly proportional to the flow velocity.

Key Features of Magnetic Flow Meters

Highly accurate with no moving parts.

Only works with electrically conductive liquids (e.g., water, slurry, acid).

Insensitive to pressure, temperature, and viscosity changes.

Provides volumetric flow rate.

Not suitable for gases or non-conductive fluids (e.g., hydrocarbons).

Working Principle: Vortex vs Magnetic Flow Meters

Let¡¯s compare how each meter works at the fundamental level:

| Feature | Vortex Flow Meter | Magnetic Flow Meter |

|---|---|---|

| Measurement Principle | Detects frequency of vortices shed behind a bluff body | Measures voltage induced by conductive fluid moving through a magnetic field |

| Physical Contact | Flow contacts internal sensor (bluff body) | Electrodes contact fluid inside pipe |

| Output Signal | Frequency proportional to flow | Voltage proportional to flow velocity |

Accuracy and Repeatability

Magnetic flow meters typically offer higher accuracy¡ª¡À0.2% to ¡À0.5% of reading, ideal for billing or precision dosing.

Vortex flow meters are slightly less accurate¡ª¡À0.75% to ¡À1% of reading¡ªbut still sufficient for many process control applications.

In terms of repeatability, both perform well, but magmeters tend to be more consistent in fluctuating conditions.

Installation Requirements

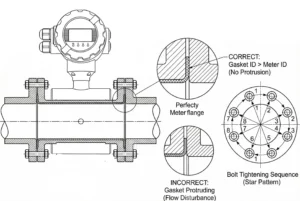

Vortex Flow Meter Installation

Requires straight pipe lengths (usually 10D upstream and 5D downstream).

Sensitive to vibrations and improper alignment.

Can be installed vertically or horizontally, as long as the pipe is full.

Magnetic Flow Meter Installation

Also requires straight runs, but often less than vortex meters.

Needs proper grounding and isolation.

Electrodes must remain fully immersed in conductive fluid at all times.

Verdict: Magnetic meters are less fussy about installation, especially in tight spaces.

Fluid Type Compatibility

This is one of the biggest deciding factors between vortex and magnetic flow meters.

Vortex Flow Meters

? Suitable for:

Clean liquids (water, solvents)

Steam (saturated and superheated)

Compressed air

Natural gas

? Not ideal for:

Dirty or viscous fluids

Slurries or highly conductive fluids

Magnetic Flow Meters

? Suitable for:

Water (clean and wastewater)

Slurries and corrosive liquids

Acids, caustics, pulp

? Not suitable for:

Steam or air

Hydrocarbons or non-conductive fluids

Durability and Maintenance

Both flow meters have no moving parts, which is a huge plus in terms of durability. However, they differ when it comes to exposure to fluid properties.

Vortex meters may suffer from vibration-induced errors and need occasional recalibration.

Magmeters require electrode cleaning if dealing with dirty or sticky fluids but are otherwise low-maintenance.

Bottom Line: Magnetic flow meters typically require less mechanical maintenance, especially for dirty or corrosive fluids.

Cost Comparison

While prices vary based on size, material, and smart features, here¡¯s a general comparison:

| Meter Type | Initial Cost | Installation Cost | Maintenance Cost |

|---|---|---|---|

| Vortex | $$ | $$ | $ |

| Magnetic | $$$ | $$ | $ |

Vortex meters are generally more affordable upfront.

Magmeters cost more initially but can save money over time through higher accuracy and lower downtime.

Application Examples

Let¡¯s see where each type of meter shines in real-world usage.

Where to Use a Vortex Flow Meter

Steam distribution in power plants or food processing

Compressed air flow in manufacturing plants

Natural gas measurement

Chilled water in HVAC systems

Where to Use a Magnetic Flow Meter

Wastewater treatment

Chemical dosing in industrial processes

Slurry flow in mining or pulp and paper

Municipal water supply systems

Pros and Cons at a Glance

Vortex Flow Meter

Pros

?? Suitable for gas, steam, and liquid

?? Lower initial cost

?? No moving parts

Cons

? Requires straight pipe runs

? Not suitable for dirty fluids

? Sensitive to vibration

Magnetic Flow Meter

Pros

?? Extremely accurate

?? Handles dirty, corrosive, or slurry-type fluids

?? Low pressure drop

Cons

? Only works with conductive liquids

? Higher initial cost

Which Flow Meter Should You Choose?

Choosing between a vortex flow meter and a magnetic flow meter depends entirely on your application needs:

| Requirement | Best Choice |

|---|---|

| Measuring steam or gas | Vortex |

| Highly accurate liquid flow | Magnetic |

| Dirty or corrosive liquids | Magnetic |

| Budget-friendly | Vortex |

| Non-conductive fluids | Vortex |

| Slurry and wastewater | Magnetic |

Conclusion

In the debate of vortex flow meter vs magnetic flow meter, there¡¯s no universal winner¡ªeach excels in specific environments. If you’re dealing with steam, gas, or clean water, the vortex flow meter is likely your best bet. But if your application involves dirty, corrosive, or slurry-like fluids, or demands high accuracy, then magnetic flow meters are unmatched.

Choosing the right flow meter is not just about technical specifications¡ªit’s about understanding your process conditions, budget, and long-term goals. By making an informed decision, you can ensure optimal performance, minimal maintenance, and maximum ROI for your flow measurement system.

Still unsure which one to choose? It¡¯s worth consulting with a flow instrumentation specialist to analyze your application in depth and avoid costly mistakes.