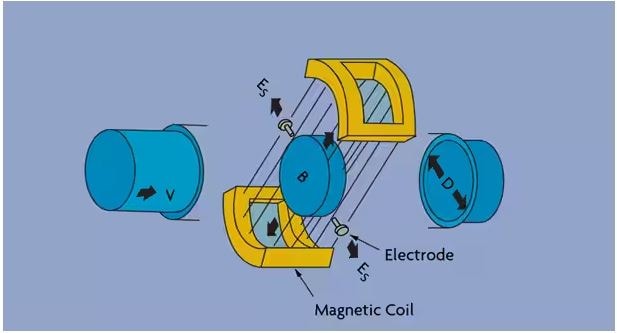

Most frequently mounted in pipes, electromagnetic flow meters are made up of a tube with coils that create a magnetic field and electrodes that pick up voltage created by the flowing fluid. According to Faraday¡¯s Law, the voltage (E) that develops across the electrodes as a conductive fluid passes through a pipe with a diameter (D) and a magnetic field density (B) produced by the coils will be proportional to the liquid¡¯s velocity (V). Since the pipe diameter and the magnetic field density are fixed, they can be added to create a calibration factor (K), which simplifies the equation to:One kind of flow meter used to measure the flow of liquid in a pipe is the electromagnetic flow meter, sometimes referred to as a magnetic flow meter or a magmeter. Faraday¡¯s Law of Electromagnetic Induction, which states that a conductor moving through a magnetic field would induce a voltage, governs how these devices work.

Electrodes on the flow tube walls sense a voltage signal in an electromagnetic flow meter when a magnetic field is created and directed into the liquid passing through the pipe. According to Faraday’s Law, the voltage produced is directly proportionate to the liquid’s flow. The fluid generates more voltage as it flows more quickly.

Electromagnetic?flow?meters?generate?signals?that?are?linear?with?flow,?in?contrast?to?many?other?flow?meter?technologies. Therefore,?without?compromising?accuracy,?the?turndown?related?to?magnetic?flow?meters?can?be?close?to?20:1?or?more.

How Do Electromagnetic Flow Meters Work?

Most frequently mounted in pipes, electromagnetic flow meters are made up of a tube with coils that create a magnetic field and electrodes that pick up voltage created by the flowing fluid. According to Faraday¡¯s Law, the voltage (E) that develops across the electrodes as a conductive fluid passes through a pipe with a diameter (D) and a magnetic field density (B) produced by the coils will be proportional to the liquid¡¯s velocity (V). Since the pipe diameter and the magnetic field density are fixed, they can be added to create a calibration factor (K), which simplifies the equation to:

E = KV

The signal-weighing factor compensates for the velocity variations at various places in the flow profile. By arranging the magnetic coils so that the magnetic flux is highest where the signal weighing factor is lowest, compensation is also achieved.

Manufacturers use water calibration of each flow tube to obtain the K factor of each magmeter. The resulting K value is linear across the whole flow meter range and is applicable to any other conductive liquid. Because of this, flow tubes are typically calibrated at a single velocity. Because changing the direction will alter the signal’s polarity but not its magnitude, magmeters can measure flow in both directions.

For non-Newtonian fluids (those with velocity-dependent viscosity) or magnetic slurries (those containing magnetic particles), the K value determined via water testing may not be reliable. The density of the magnetic field within the tube may be impacted by these kinds of fluids. For both of these fluids, special compensatory designs and in-line calibration should be taken into account.

Common Applications for Electromagnetic Flow Meter

Electromagnetic flow meters can detect the flow of clean, multi-phase, dirty, corrosive, erosive, or viscous liquids and slurries as long as their conductivity exceeds the minimum required for the particular design. These devices are widely used across various industries due to their accuracy, reliability, and ability to measure the flow of conductive liquids without any moving parts.

Some key applications include:

Water and Wastewater Treatment

- Electromagnetic flow meters excel in handling clean water, raw sewage, sludge, and chemicals used in treatment processes.

- They offer high accuracy and no pressure drop, which is essential for large-scale municipal water management.

- Since they have no moving parts, they are highly resistant to debris and solid particles present in wastewater.

Chemical Processing

- Magmeters can measure aggressive and corrosive liquids ¨C like acids, alkalis, and other chemical solutions without being damaged.

- They are available with corrosion-resistant linear materials (e.g., PTFE, PFA) to withstand harsh chemicals.

- No obstruction in the flow path means they do not get clogged or affected by sedimentation.

Food and Beverage Industry

- Used for measuring milk, beer, juices, syrups, and other food-grade liquids that require hygienic conditions.

- Magmeters can be designed with sanitary fittings (e.g., stainless steel) to met FDA and EHEDG standards.

- Their non-intrusive design ensures there is no contamination or disruption in the production process.

Pulp and Paper Industry

- Capable of handling high-viscosity and fiber-laden fluids ¨C such as pulp slurries and coating solutions.

- No moving parts means minimal wear and tear ¨C even when dealing with abrasive slurry.

- Provides consistent measurement despite fluctuations in fluid density and composition.

Mining and Mineral Processing

- Used for measuring the flow of mineral slurries and abrasive fluids in extraction refining operations.

- Their rugged construction allows them to withstand harsh environmental conditions.

- No mechanical wear from abrasive particles ensures long-term reliability and low maintenance.

Power Generation (Cooling Water and Boiler Feedwater)

- Commonly used in thermal and nuclear power plants for monitoring cooling water and feedwater flow rates.

- They can handle large pipe sizes and provide highly accurate measurement for flow monitoring and efficiency calculations.

- No moving parts means they can operate in high-temperature environments with minimal maintenance.

Pharmaceutical and Biotechnology

- Used for measuring the flow of purified water, solvents, and active pharmaceutical ingredients with high precision.

- Electromagnetic meters with sterile designs and CIP/SIP (clean-in-place/steam-in-place) compatibility are ideal for pharmaceutical applications.

- Non-contact measurement ensures sterility and compliance with industry regulations.

Agriculture and Irrigation Systems

- Ideal for monitoring the flow of water, fertilizers, and pesticide solutions in irrigation systems.

- Can operate in low-pressure systems without causing significant pressure loss.

- Their long lifespan and minimal maintenance make them cost-effective for agricultural use.

Oil and Gas (Produced Water and Brine Injection)

- Used for monitoring produced water, brine injection, and chemical dosing in upstream and downstream operations.

- Their ability to measure conductive fluids with high accuracy makes them ideal for these applications.

- Explosion-proof and hazardous area-rated designs ensure safe operation in oilfield environments.

Steel and Metal Industry

- Used for monitoring the flow of cooling water in continuous casting and rolling mill operations.

- Provides accurate flow readings in high-temperature environments without mechanical failure.

- Can handle scale-laden water without clogging or performance degradation.

Application Cautions for Magnetic Flow Meters

Do?not?use?a?magnetic?flow?meter?near?its?electrical?conductivity?limit,?since?it?may?switch?off. Allow?for?variations?in?composition?and?operating?conditions?that?may?affect?the?liquid’s?electrical?conductivity.

Magnetic flow meters are typically sized to have a maximum flow velocity of about 2-3 meters per second. Differential pressure limits and/or process factors may preclude the use of this broad guideline. Gravity fed pipes, for example, may necessitate a larger magnetic flow meter to lower the pressure drop and allow the necessary amount of liquid to travel through the magnetic flow meter without clogging the piping system. In this example, using the same flow rate in the larger flow meter will result in a lower liquid velocity than the smaller flow meter.

For slurry operation, magnetic flow meters should be sized to function beyond the velocity at which solids settle (usually 1 ft/sec), to avoid clogging the pipe with sediments that can distort the measurement and potentially stop flow. Magnetic flow meters for abrasive service are often designed to run at low velocity (normally less than 3 ft/sec) to reduce wear. Despite increased wear, the flow meter should be operated above the velocity at which solids settle when used in abrasive slurry applications. These difficulties may alter the flow meter’s range, resulting in a different size than that required for an equivalent flow of pure water.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase -KFBEST