Flow measurement is one of the most critical elements in industrial processes, water management, and utility systems. In 2025, insertion electromagnetic flow meters have emerged as game-changers in fluid measurement, offering cost-efficiency, scalability, and exceptional accuracy for a wide variety of applications. These devices are not only redefining flow measurement but also significantly reducing operational costs and improving system efficiency.

In this article, we’ll explore why insertion electromagnetic flow meters are revolutionizing flow measurement, how they work, their benefits, and what sets them apart from traditional meters in today’s competitive industrial landscape.

What Is an Insertion Electromagnetic Flow Meter?

An insertion electromagnetic flow meter (often called insertion magmeter) is a type of flow meter that operates based on Faraday’s law of electromagnetic induction. Unlike full-bore magnetic meters, which require cutting the pipeline to insert the meter inline, insertion models are inserted through a small opening in the pipe wall.

These meters measure fluid velocity to calculate flow rate and are particularly suited for large diameter pipes, where full-bore meters would be impractical or too expensive.

How Insertion Electromagnetic Flow Meters Work

Insertion magmeters work by generating a magnetic field across the pipe’s cross-section. As a conductive fluid flows through this field, it induces a voltage that is directly proportional to the velocity of the fluid. Electrodes inside the probe detect this voltage, and the meter’s electronics convert it into flow rate data.

This method is non-intrusive and obstruction-free, meaning there are no moving parts or pressure drops, making it ideal for many industrial applications.

Key Advantages of Insertion Electromagnetic Flow Meters

Here’s why industries in 2025 are flocking to insertion magmeters:

✅ Lower Installation Costs

Traditional inline flow meters often require cutting pipes or shutting down operations. Insertion meters can be installed without fully dismantling pipelines, often under pressure, which saves time and labor.

✅ Ideal for Large-Diameter Pipes

Full-bore magmeters become extremely expensive for pipe diameters above 300 mm. Insertion meters offer a scalable solution for pipes ranging from 150 mm to over 2000 mm, at a fraction of the cost.

✅ Minimal Maintenance

Since these meters lack moving parts, wear and tear is minimal. This reduces maintenance frequency and extends the service life of the meter, even in harsh environments.

✅ Bidirectional Measurement

Insertion electromagnetic flow meters can measure flow in both directions, an essential feature in systems with variable flow directions, such as water distribution networks.

✅ Accuracy and Repeatability

Though not as precise as high-end inline meters, modern insertion magmeters can achieve accuracy up to ±1% of the flow rate, which is more than sufficient for most utility and industrial applications.

Energy Sector: A Critical Use Case

The power generation and energy sectors require accurate flow data to manage cooling water systems, monitor chemical dosing, and ensure environmental compliance.

Insertion electromagnetic flow meters are increasingly used in:

-

Cooling water circuits

-

Condensate return lines

-

Fuel and chemical injection systems

Their resistance to high temperature and pressure conditions makes them highly reliable even in demanding energy applications.

Enhancing Smart Industry & IIoT Integration

In 2025, Industrial Internet of Things (IIoT) is more than a buzzword—it’s a necessity. Modern insertion electromagnetic flow meters are designed with smart features, including:

-

Digital communication protocols (Modbus, HART, Profibus)

-

Remote diagnostics and calibration

-

Cloud connectivity for real-time monitoring

These features allow industries to automate decision-making, perform predictive maintenance, and optimize operations, all while minimizing manual intervention.

Comparison With Traditional Flow Meter Technologies

Let’s compare insertion electromagnetic flow meters with other popular flow meter types:

| Feature | Insertion Magmeter | Ultrasonic | Turbine | Vortex |

|---|---|---|---|---|

| Obstruction-Free Flow | ✅ | ✅ | ❌ | ❌ |

| Suitable for Large Pipes | ✅ | ✅ | ❌ | ❌ |

| Maintenance Requirements | Low | Moderate | High | Moderate |

| Installation Cost | Low | High | Medium | Medium |

| Accuracy | Medium-High | High | High | High |

| Suitable for Dirty/Conductive Fluids | ✅ | ❌ | ❌ | ❌ |

Clearly, insertion magmeters hit the sweet spot between performance, cost-efficiency, and ease of use—making them a superior option for many applications.

Important Considerations When Choosing a Meter

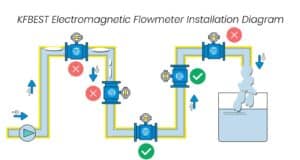

To get the best out of insertion electromagnetic flow meters, keep in mind:

-

Fluid Conductivity: Must be above a minimum threshold (usually 5 µS/cm).

-

Straight Pipe Length: Ensure enough straight length before and after the sensor to avoid turbulence.

-

Installation Orientation: Horizontal or vertical installation depends on the application.

-

Probe Depth: Must be positioned at a specific depth within the pipe’s diameter for accurate velocity measurement.

Choosing the right model based on pipe diameter, fluid type, and system pressure is critical for reliable performance.

Environmental and Sustainability Impact

In 2025, sustainability goals are front and center across industries. Insertion electromagnetic flow meters help organizations:

-

Reduce water waste

-

Optimize resource usage

-

Lower energy consumption

By integrating with environmental monitoring systems, they enable real-time compliance tracking with environmental regulations, a major advantage in regions with strict sustainability mandates.

What the Future Holds for Insertion Magmeters

With rapid advancements in sensor technology and data analytics, the future of insertion electromagnetic flow meters looks bright:

-

AI-driven calibration and self-diagnostics

-

Enhanced battery-powered models for remote locations

-

Wireless data transmission and integration with cloud SCADA systems

-

Smaller form factors for use in compact industrial setups

As industries strive for digital transformation, insertion magmeters will be at the heart of smart flow monitoring systems.

Conclusion: The Insertion Flow Meter Revolution Is Here

In 2025, insertion electromagnetic flow meters are no longer a niche solution—they are mainstream. Their ability to combine cost-efficiency, durability, and smart features makes them the go-to flow measurement tool for water utilities, energy producers, and industrial giants alike.

Whether you’re upgrading your legacy system or deploying a brand-new smart flow monitoring solution, insertion magmeters offer unmatched value. Their ease of installation, minimal maintenance, and compatibility with digital systems make them a top choice for organizations looking to future-proof their operations.

If you’re serious about modernizing your flow measurement approach—now is the time to make the switch. Insertion electromagnetic flow meters are not just improving measurement; they’re redefining what’s possible.

We are a manufacturer of automatic flow meters with many years of experience in the industry. We have strong independent research and development capabilities and are a leader in the flow meter industry. Our main products include electromagnetic flow meters, vortex flow meters, turbine flow meters, ultrasonic flow meters, Coriolis flow meters, various solenoid valves, level meters, control units and valves, etc. Welcome to purchase –Best Instrument