In today’s industrial landscape, accurate flow measurement is vital across sectors—from oil & gas and water treatment to food processing and pharmaceuticals. But not all flow meters are created equal. Choosing the right type depends on fluid characteristics, installation constraints, accuracy needs, and cost.

This comprehensive guide dives into the 12 most common types of flow meters, breaking down how each works, their key benefits, and potential drawbacks. Whether you’re an engineer, plant manager, or decision-maker, this article will help you find the best flow meter for your application.

1. Electromagnetic Flow Meter (Magmeter)

How it works:

Uses Faraday’s law to measure flow of conductive liquids by detecting voltage induced by fluid movement in a magnetic field.

✅ Advantages:

-

No moving parts (low maintenance)

-

Highly accurate (±0.5%)

-

Ideal for dirty, corrosive, or slurry liquids

-

Minimal pressure drop

❌ Disadvantages:

-

Only works with conductive fluids

-

Not suitable for hydrocarbons or gases

-

Higher upfront cost

2. Ultrasonic Flow Meter

How it works:

Uses sound waves to measure flow velocity. Comes in transit-time and Doppler types. Often clamp-on, non-intrusive.

✅ Advantages:

-

Non-invasive (no pipe cutting)

-

Works with wide pipe sizes

-

No pressure loss

-

Ideal for retrofits or temporary setups

❌ Disadvantages:

-

Accuracy depends on pipe condition and fluid type

-

Struggles with very low flow rates

-

Higher cost than mechanical meters

3. Turbine Flow Meter

How it works:

Fluid turns a rotor inside the meter body. The rotational speed is proportional to flow rate.

✅ Advantages:

-

High accuracy (±0.2–1%)

-

Good for clean, low-viscosity fluids

-

Fast response time

❌ Disadvantages:

-

Mechanical parts prone to wear

-

Not suitable for dirty or viscous fluids

-

Requires flow conditioning

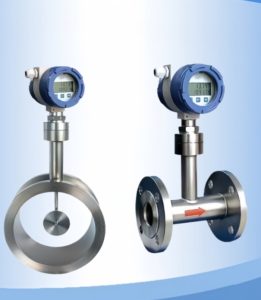

4. Vortex Flow Meter

How it works:

Detects vortices (swirls) formed as fluid flows past a bluff body in the pipe. Vortex frequency = flow rate.

✅ Advantages:

-

No moving parts

-

Good for steam, gas, and liquids

-

Medium accuracy (±1%)

❌ Disadvantages:

-

Not suitable for very low flow rates

-

Can struggle with pulsating flows

-

Installation needs straight pipe lengths

5. Coriolis Flow Meter

How it works:

Measures mass flow by detecting phase shift in vibrating tubes caused by fluid movement.

✅ Advantages:

-

Measures mass flow directly

-

High precision (±0.1–0.2%)

-

Handles varying densities well

-

Suitable for aggressive or viscous fluids

❌ Disadvantages:

-

Expensive

-

Sensitive to vibration

-

Heavy and bulky

6. Thermal Mass Flow Meter

How it works:

Measures the amount of heat carried away by a gas as it flows past a heated sensor.

✅ Advantages:

-

Accurate gas flow measurement

-

No moving parts

-

Excellent for low flow gas monitoring

❌ Disadvantages:

-

Not for liquids

-

Accuracy affected by gas composition

-

Requires recalibration for different gases

7. Positive Displacement (PD) Flow Meter

How it works:

Captures fluid in rotating components (gears, pistons, etc.) and counts the volume mechanically.

✅ Advantages:

-

High accuracy (±0.1%)

-

Works well with high-viscosity fluids

-

No flow conditioning required

❌ Disadvantages:

-

Wear and tear on moving parts

-

Not suitable for dirty or solid-laden fluids

-

Requires regular maintenance

8. Open Channel Flow Meter (Weirs and Flumes)

How it works:

Measures flow in non-full pipes or channels using gravity flow and level measurement.

✅ Advantages:

-

Ideal for irrigation, stormwater, and wastewater

-

Simple, cost-effective for large volumes

-

No power needed (in manual setups)

❌ Disadvantages:

-

Accuracy impacted by debris and sediment

-

Only for open channels

-

Requires specific installation and calibration

9. Variable Area (Rotameter) Flow Meter

How it works:

A float inside a tapered tube rises or falls based on flow rate, giving a visual or electronic reading.

✅ Advantages:

-

Simple and low-cost

-

Easy to read and install

-

No power required (in analog versions)

❌ Disadvantages:

-

Low accuracy (±2–5%)

-

Not suitable for thick or dirty fluids

-

Requires vertical installation

10. Differential Pressure (DP) Flow Meter

How it works:

Measures pressure drop across a constriction (like an orifice plate) to determine flow rate.

✅ Advantages:

-

Well-understood and widely used

-

Inexpensive hardware

-

Suitable for steam, gas, and liquids

❌ Disadvantages:

-

Pressure loss due to restriction

-

Accuracy depends on calibration and maintenance

-

Requires long straight runs of pipe

11. Target Flow Meter

How it works:

A flat disc (target) is suspended in the fluid path. Flow-induced force on the target is measured.

✅ Advantages:

-

Suitable for low-flow and high-viscosity applications

-

Durable in harsh conditions

-

Compact design

❌ Disadvantages:

-

Mechanical wear on the target

-

Limited accuracy compared to modern meters

-

Not ideal for fast-changing flows

12. Insertion Flow Meter (e.g., Insertion Magmeter or Thermal)

How it works:

Sensor is inserted into a pipe wall to measure flow velocity or temperature-based heat loss.

✅ Advantages:

-

Low cost for large pipe applications

-

Minimal installation effort

-

Works under pressure (hot tap)

❌ Disadvantages:

-

Accuracy is lower than full-bore meters

-

Must be inserted at the correct depth

-

Can be affected by turbulence or poor placement

Conclusion: Which Flow Meter Is Best for You?

There’s no one-size-fits-all flow meter. The best choice depends on:

-

Fluid type: Liquid, gas, steam, clean, dirty, viscous?

-

Application: Industrial, municipal, process control, batching?

-

Accuracy vs. cost: Are you measuring for billing, compliance, or rough estimation?

-

Pipe size and material: Can you cut into the pipe? Do you need a non-invasive solution?

Pro Tip: Always consider lifecycle costs—including installation, calibration, maintenance, and expected service life.