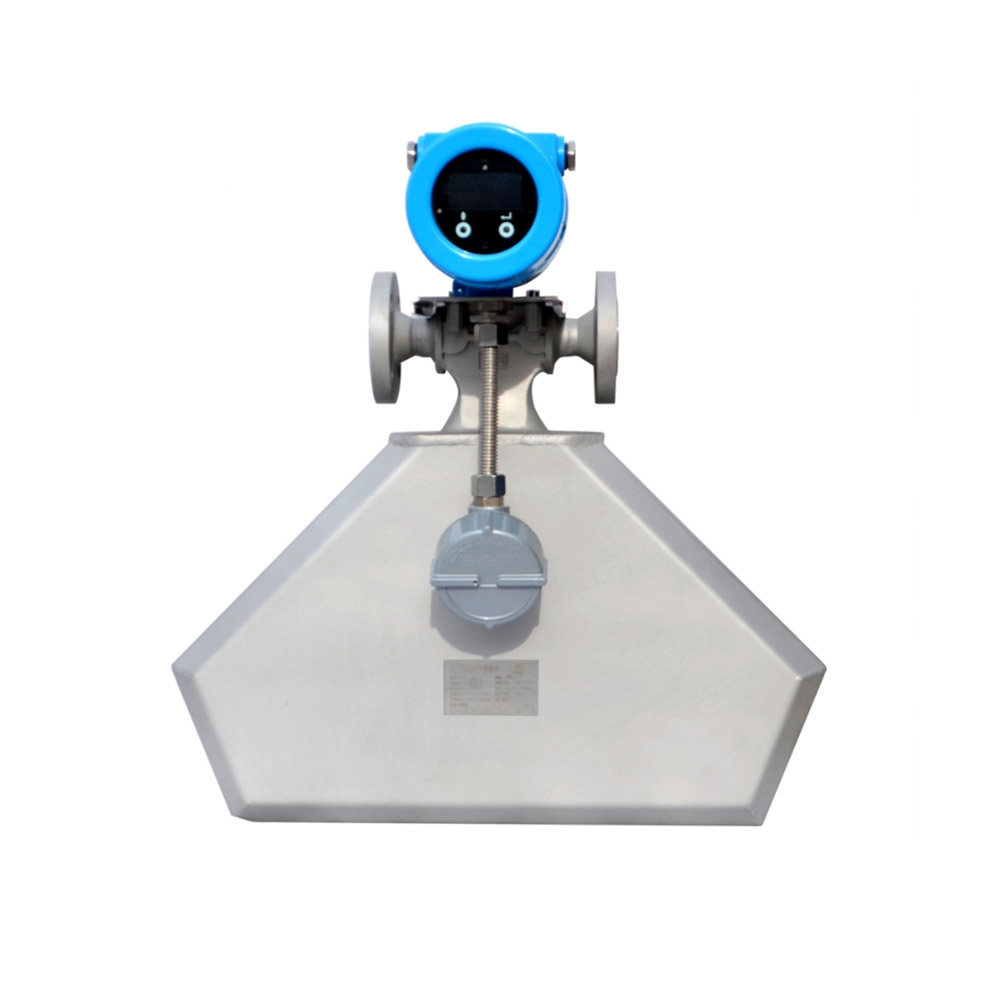

Coriolis Mass Flowmeter: Directly measures mass flow with extremely high accuracy, unaffected by fluid pressure, temperature, or density, setting the benchmark for precision measurement.

| DN | DN3 ~ DN250 |

| Accuracy | 0.1%R / 0.2%R |

| Power supply | 220VAC / 24VDC |

| Medium | Gases and Liquids |

| Shape | U-shaped, straight pipe type, micro-bent type |

The Coriolis Mass Flowmeter measures fluid mass flow directly based on the Coriolis effect, offering extremely high accuracy without the need for temperature or pressure compensation. It is unaffected by media properties such as density, viscosity, and conductivity, enabling precise measurement of various liquids and gases. In addition to mass flow, it can simultaneously measure volumetric flow, density, and temperature, providing comprehensive data for process control. It is widely used in industries like petrochemicals, pharmaceuticals, food, and new energy, where stringent flow measurement accuracy is critical.

Features: